Contents

It is very difficult to organize a stable fermentation process without a water seal. Experienced home winemakers and moonshiners know this. Although nowadays you can buy a factory water seal, it’s easier to make this device with your own hands from improvised materials, spending just a few minutes. We will consider the most successful designs further.

Why do you need a water seal

During fermentation, carbon dioxide is actively released (approximately 4 cubic meters per 1 liter of alcohol obtained). The accumulation of carbon dioxide is fraught with high pressure in the fermentation tank, which can lead to an explosion. The gas must be removed, but do it in such a way that oxygen does not enter the container. The fact is that oxygen activates the vital activity of bacteria that convert alcohol into acetic acid, and without air access, these bacteria are inactive.

A fermentation airlock is a valve that removes carbon dioxide while preventing air from entering. Without this device, winemaking is impossible, otherwise the young wine immediately turns into vinegar. Moonshiners are still arguing about its necessity, but beginners are better off installing it.

There is an opinion that the mash should “breathe”, so a water seal is not needed. In fact, mash oxidizes no worse than wine. Just during the period of active fermentation, the carbon dioxide released prevents oxygen from reaching the surface. But as soon as the alcohol bacteria do their job, their vinegar “colleagues” immediately get to work, turning alcohol into acid. If such a mash is not overtaken in time, then it will simply turn sour or an unpleasant sour taste will appear in the moonshine. The exit rate also drops.

Braga under a water seal can stand without distillation for much longer and not oxidize. All the alcohol produced by our friendly bacteria is preserved.

Next, we will look at 3 of the best homemade water lock designs for wine and mash (universal options).

Options for water locks for mash and wine

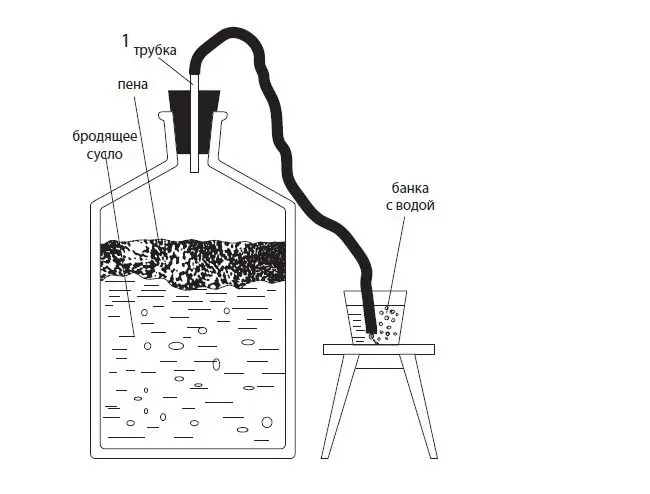

1. Classic water seal (lid, tube, jar)

The simplest and most reliable kit. It is enough to make a hole in the lid of the fermentation tank, insert the tube and seal the junction with glue. Dip the other end into a jar of water.

Disadvantage: with a small diameter of the tube, the water seal can become clogged with foam, so I recommend using not thin capillaries, but tubes of large diameter.

This water lock allows you to accurately determine the readiness of wine or mash. If there are no bubbles in a jar of water for 1-2 days, then the unsweetened mash is ready for distillation, and the wine is ready to be drained from the sediment.

One of the varieties of this design is a water seal from a dropper. More on video.

During fermentation, an unpleasant odor appears. This is very important for residents of apartments who are not able to take out a container with mash to a non-residential premises. You can get rid of the smell by removing carbon dioxide into the sewer. It is only necessary to improve the jar into which fermentation products fall.

Gas through the tube from the fermentation tank enters the jar, overcomes the pressure of the liquid column (h) and goes into the sewer. The column of water serves as a kind of barrier that does not allow gases from the sewer to enter the fermentation tank.

This design resembles a steamer for a moonshine still. Two holes are made in a jar with a tight lid, then they are connected to tubes and sealed. A modernized half-liter jar is filled with 1/3 of the volume with water, the inlet tube is lowered into the liquid by 1-2 cm, the outlet tube into the washbasin.

2. Medical glove

Simple design suitable for wide mouth fermentation containers (jars and bottles). In fact, this is not a water seal, but it works no worse. The glove lock is often used by women, since its construction does not require anything to be drilled, soldered and glued.

A small hole is made in any of the fingers of a rubber glove with a needle. Next, the glove is put on the neck of the container. So that the gas pressure does not tear off the glove, the attachment point with the neck is covered with an elastic band or tied with a thread.

Disadvantage: due to the too large neck diameter and high gas pressure on containers with a volume of more than 20 liters, it is very difficult or even impossible to securely fasten the glove. The smell of fermentation will be present in the room.

With active fermentation, the glove inflates, when the process ends, it deflates again.

3. Cotton plug

The neck of the container is plugged with a stopper made of cotton wool or other porous material, through the structure of which carbon dioxide can escape. But the cork does not provide complete tightness, especially at the very end of fermentation. The pressure in the bottle drops, as a result of which air begins to enter the container. Another disadvantage is that it is very difficult to understand when fermentation has ended.

A cotton plug is used if for some reason it is not possible to install a more reliable design.

Shop water seals for mash and wine

Factory water locks of various designs appeared on sale, including those built into lids for cans. The price is low, and the ease of use and reliability are at an excellent level.