Contents

As you know, the shades of taste of “living water” strongly depend on the place of manufacture, however, the general technology for the production of whiskey remains approximately the same in all countries. In this article, we will figure out what and how whiskey is made from, take a closer look at all the stages and touch a little on the characteristic features of individual regions.

Whiskey composition. The basic ingredients are always the same: malt (sprouted grain), yeast and water. Sometimes a little sugar or caramel is added to the finished drink, but this applies more to cheap varieties. Flavorings, dyes and other chemical additives in this whiskey can not be.

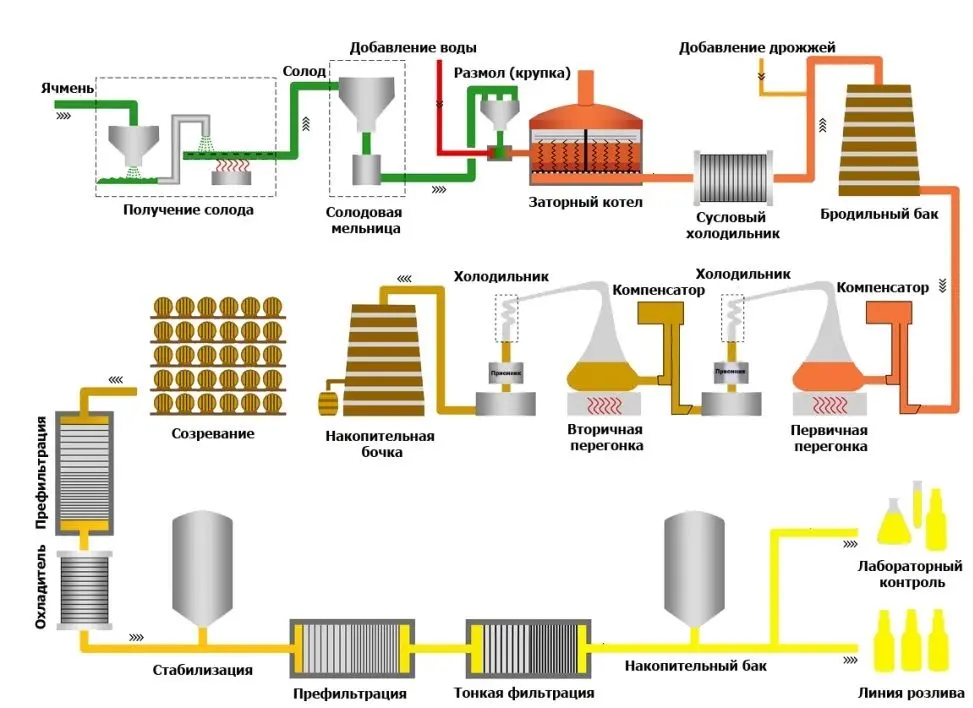

Step by step manufacturing technology

Malposition

Whiskey is made from pure barley or a mixture of grains, for example, bourbon (American whiskey) is at least 51% corn, and the rest is other cereals (barley, rye, etc.), pure rye or wheat varieties are also possible . Rarely, but there are whiskeys made from rice, buckwheat, and other cereals.

Dried in a sunny, well-ventilated room, the grains are poured with water and left to germinate, periodically changing the water – this is how enzymes are activated in cereals that break down starch into simple sugars. Sprouted grain is called malt. The whole process takes up to two weeks. The main thing is to stop the malting of grains in time so that the sprouts do not “eat up” all the starch that will be needed in the next stages.

Whiskey made from unmalted (unsprouted) raw materials is called “grain”. In fact, it is a barrel-aged ordinary spirit with a rough taste and almost no aromatic bouquet. Grain whiskey is not sold as a separate drink, but is only mixed into blends with “noble” distillates.

Drying malt

The finished malt is removed from the water and dried in a special chamber. In Scotland, on the Isle of Islay and in Japan, the smoke of swamp peat is additionally used to make the drink acquire a characteristic “smoked” taste and smoky aroma.

Cooking Wort

The wort is made like this: dry malt is cleaned of impurities, subjected to several tests for moisture levels, parasite infestation, etc. The germinated and dried grains that have passed the test are ground into coarse flour and subjected to the mashing process (mixing with water).

Grinding is poured into a wort kettle, poured with water and gradually heated, not forgetting to stir. The future wort sequentially goes through several temperature regimes with sustained temperature pauses:

- 38-40 ° C – flour and water turn into a homogeneous mass;

- 52-55°C – protein is broken down;

- 61-72 ° C – starch is saccharified (turns into sugar suitable for yeast);

- 76-78°C – the final sugary substances are formed.

Fermentation

The wort is poured into wooden or steel vats and mixed with special alcoholic yeast (each reputable enterprise tries to have its own unique strain). In many distilleries, yeast is taken from a previous batch of mash, as a result, the process becomes cyclical and lasts for tens, and sometimes hundreds of years.

Fermentation takes 2-3 days at a temperature of about 37 degrees. Yeast actively multiply, feeding on oxygen, but when the oxygen in the mash ends, the breakdown of sugar obtained from starch in the grain begins.

At the end of this phase comes the time of malolactic fermentation – the fermentation of the wort due to lactic acid bacteria, and not yeast. Ready-to-distill mash with a strength of 5% tastes like beer, but without hops.

Distillation

The mash that has won back is subjected to double or triple distillation (depending on the manufacturer) in copper distillation cubes – alambiks. The material of the equipment is very important: copper eliminates the “sulphurous” taste of alcohol and provokes chemical reactions, as a result of which vanilla, chocolate and nutty tones appear in the whiskey bouquet. However, stainless steel equipment is sometimes installed in new industries.

After the first distillation, the mash turns into a “weak wine” with a strength of ~ 30 degrees. To get a 70-degree whiskey, you need to carry out a second distillation.

For further production of whiskey, only the middle portion (“heart”) is used, the first and last fractions (“heads” and “tails”) are drained or sent to a distillation column to obtain pure alcohol. The division into fractions is due to the fact that at the beginning and end of the distillation process, a lot of harmful substances enter the finished drink.

Even the shape of the alambic matters: each notch on the copper side affects the taste of the distillate. Therefore, when equipment is changed at old distilleries, the new one is cast exactly according to the patterns of the former, retaining all defects, “bends” and dents.

For the production of grain whiskey and bourbon, the Coffey continuous distillation apparatus is often used instead of the traditional two-chamber alambique. This device distills the mash not in portions, but constantly. This method of production saves time and distillation costs, but degrades the quality of the whisky.

The finished distillate is diluted with soft spring water to 50-60 degrees. Some distilleries prefer hard water with a high content of trace elements, such whiskey acquires a characteristic mineral flavor.

Exposure

Traditionally, whiskey is aged in oak sherry casks, but for cheap varieties, sometimes they take bourbon containers (American whiskey “ages” in new, charred casks) or even completely new, unused casks.

At this stage, the bouquet of the drink is finally formed, a noble caramel shade and aroma appears. At the same time, 6 main processes take place:

- Extraction (“pulling out” of wood aroma, tannins).

- Evaporation (barrels are not closed hermetically, alcohol gradually evaporates).

- Oxidation (of aldehydes when interacting with the barrel material).

- Concentration (the smaller the volume of the liquid, the richer the aroma).

- Filtration (through membrane filters, immediately before blending or bottling).

- Colorization (using caramel to make the drink look “nobler”).

The average aging period is 3-5 years, but there are varieties that spend 30 years or more in barrels. The longer the whiskey is aged, the greater the “angel’s share” – the amount of alcohol evaporated – and the higher the price. Over time, oak wood absorbs most of the fusel oils from alcohol, saturates the drink with lactones, coumarin and tannin, but if overexposed, the whiskey will acquire a “woody” flavor.

Blending

It is a process of mixing distillates (sometimes grain alcohols are also added to the composition) of different aging periods and (or) from different distilleries. There is no single recipe: each brand has its own secrets. The number of mixed varieties can reach up to 50, and all of them will differ in taste and aging. The proportions are selected by an experienced master of production – a blender. Typically, such a person has been working at the enterprise for decades and, long before retirement, prepares a replacement for himself from among other employees, gradually passing on secrets and best practices.

The point of blending is to guarantee the buyer the same taste of their favorite brand from year to year, regardless of the characteristics of the crop or technology. Also, mixing allows you to create new whiskey with a unique taste (will expand the range of products) from distillates available to the company, changing only the proportions.

Blending is not a mandatory step: many connoisseurs prefer to drink pure single malt whiskey produced by one distillery, this category is called “single malt”, and blended whiskey is labeled “blended”. Arguments about the superiority of one category over another do not make sense, it is more a matter of taste and philosophy than the real impact of production technology on quality.

Blended whiskey is aged in oak barrels for several more months, so that mixed varieties “marry” – turn into one harmonious drink, and not a cocktail of flavors.

Bottling

After the final aging, the whiskey is filtered (mechanically, to separate the liquid from particles of wood, other solid fractions), sometimes the drink is again diluted with water until the strength prescribed by the regulations is obtained. Only after that the finished product is bottled and sent to stores.

Cheap distilleries sometimes practice the questionable method of cold filtration, where the whiskey is chilled to around -2°C. As a result, fatty acids float to the surface and are easily removed mechanically. After cold filtration, whiskey loses some of its organoleptic properties (aroma and taste), but it looks more presentable – it does not become cloudy in a glass when ice is added, it seems amber and transparent.