Contents

Previously, poultry farms and large farms were engaged in cage keeping of chickens. Now this method is becoming more popular every day among poultry farmers. Why the cage keeping of poultry at home is in demand, and we will now try to find out how to build cages for chickens on our own.

Features of cell design and requirements for them

Chickens are considered unpretentious birds, they are easy to keep and breed at home, but for maximum productivity they need to equip comfortable housing. When making cells with your own hands, you need to take into account important nuances, and know what requirements are imposed on them:

- An important indicator is the size of the cages for chickens, which determines the egg production and growth of the bird. Always take into account the number of heads and breed. If you take the same number of heads, then laying hens require less space in an enclosed space than meat poultry.

- Each cage for chickens must be equipped with a feeder and drinker.

- In cages, all walls, ceiling, and floor must be slatted without blind areas. It is allowed to install a solid floor if flooring is provided.

- It is especially important to pay attention to the floor. When making it at home, you need to take a rigid mesh so that it does not bend under the weight of adult chickens.

- In the manufacture of cells, the mesh is used only fine-meshed. This requirement is aimed at protecting birds from the encroachments of small rodents, such as weasels. The maximum mesh size of 50×100 mm is allowed only on the front wall of the cage so that the chicken can stick its head to the feeder.

- The place where chickens are kept in cages should be dry, without drafts and warm. In winter, a barn is used for these purposes. In summer, cages can be taken outside, only they need to be placed under a canopy to protect from rain.

If these requirements are taken into account when making cages at home, the poultry farmer can already hope for a positive result.

The video shows cages for keeping chickens:

What are the cells

Factory-made cells are produced according to the established standard. Experienced poultry farmers are trying to improve home-made designs to their taste. In any case, all cells have a common feature, and they are divided into two types:

- Cage with lining. For this type of construction, a solid plywood or board floor is provided. A bedding of straw or sawdust is poured on top.

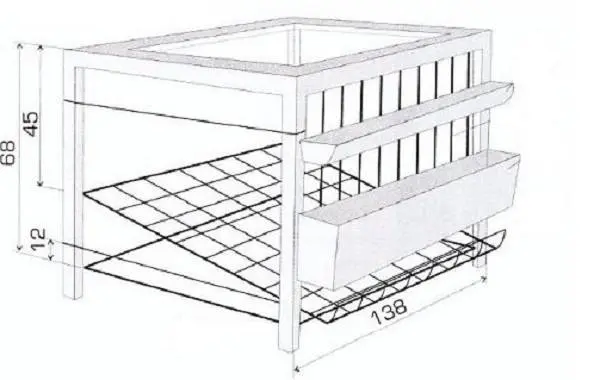

- A cage with a slatted floor, at the end of which an egg collector is made. This type of construction has a sloping floor made of mesh. The end of the floor beyond the boundaries of the front wall smoothly passes into the egg collector. Under the grid there is a retractable tray for removing litter. The egg laid by the laying hen rolls down the sloping floor into the egg collector, and the droppings through the net fall onto the pallet. Inside such a cage is always clean and dry.

You can make any of these designs yourself. For laying hens, their size is usually calculated on 7-10 heads. For a large number of chickens, you can assemble a battery of several cages stacked on top of each other.

The video provides an overview of the cells:

Positive and negative aspects of the cell content of chickens

Keeping chickens in cages has many opponents and supporters. There are a lot of opinions on this matter. We will now try to characterize the positive and negative aspects of closed poultry keeping.

Let’s start with the negatives:

- The closed space restricts the movement of chickens. For a mobile bird, such oppression affects the decrease in egg production.

- Chickens are not exposed to sunlight. The lack of vitamin D has to be filled with nutritional supplements.

- Food is limited to natural top dressing in the form of fresh grass, worms and insects. The deficiency of minerals must be replenished with the same additives.

- A confined space is prone to the rapid development of infection. Sick birds come into close contact with healthy birds, causing rapid infection.

However, there are also positive aspects of the cellular content of chickens:

- In cages, chickens are protected from predators.

- Easier bird control. A sick chicken can be noticed faster, and it can be helped in a timely manner.

- Wild birds are carriers of infection. Such contact is excluded when chickens are caged.

- In cages, it is easier to provide optimal conditions for prolonging the egg-laying period. Moreover, the process of collecting eggs is simplified. The poultry breeder will not have to look for them throughout the yard.

- When kept indoors, food is significantly saved, since the possibility of eating it by wild birds is excluded.

- Cage content allows the poultry farmer to place a large number of chickens in a small area.

Summing up, it can be noted that the closed keeping of chickens will benefit the bird only with careful care.

The video shows cages for broilers and laying hens:

We determine the dimensions and draw up drawings of cells

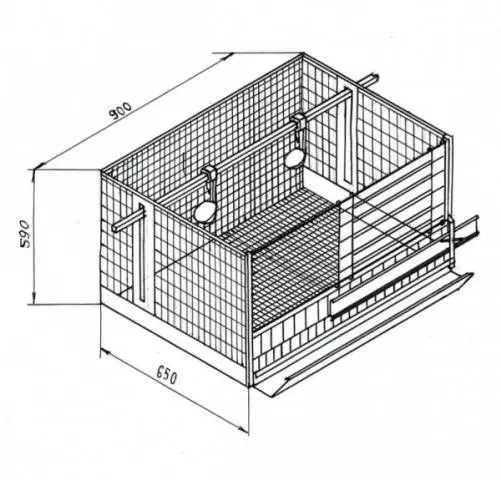

Before building cages for chickens, you need to determine its size, and then draw up an approximate drawing. The photo shows a design diagram with an egg collector. This option is considered the most convenient and popular among poultry farmers.

To build such a structure, you need to build a frame. It can be made of metal or wood. The walls, ceiling and floor are made of mesh.

The disadvantage of this design is the inconvenience of maintenance. Chickens are bad to plant and remove from such a cage.

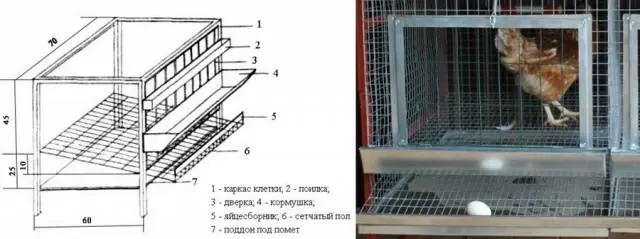

The following photo shows a detailed drawing of a chicken cage, where all its constituent parts are indicated.

Next, you need to accurately calculate the size of the cage for chickens, because productivity, as well as the comfort of the bird, depends on it. Dimensions are calculated taking into account the breed of chickens and the number of livestock.

When making cages at home for ordinary layers, you can adhere to the following calculations:

- For keeping two or three laying hens, about 0,1–0,3 m is allocated for each head.2 free area. The approximate dimension of the structure is 65x50x100 cm. The dimensions are listed in order: height, depth and width.

- For five laying hens, 0,1–0,21 m is allocated for each head2 area. Housing dimensions remain almost the same, only the length increases to 150 cm.

- For ten or twelve layers, 0,1–0,22 m are allocated2 free area. In this case, the dimensions of the cell are 70X100x200 cm. The data are given in the same order. The depth can be made different, but not less than 70 cm.

In general, it is recommended to keep a maximum of 7 birds in one cage. With a large number of chickens, it is better to build several smaller structures than one large one. Otherwise, it will be difficult to take care of the chickens, since the dropping tray will be very heavy. In addition, a reinforced frame will be required so that the structure does not sag under the weight of the birds.

What you need to work

To independently make cages for chickens, you will need to build a frame. A bar with a section of 40×40 mm is suitable for him, but wood is not the best material for this design. It is optimal to use a galvanized profile. The feeders and pan are made of galvanized steel, but it is better to use stainless steel, as it does not oxidize. The floor, walls and ceiling are made of mesh with a mesh size of 125×25 or 25×50 mm. The front wall can be made from wire, and you can also use a mesh with a mesh size of 50×50 or 50×100 mm.

Manufacturing procedure

Now we will consider the sequence of the process, which will help the novice poultry farmer decide how to make cages for keeping chickens himself.

So, the assembly of the structure begins with the frame. Billets are cut from a profile or timber, and a rectangular box is assembled from them. You can strengthen the frame with additional jumpers installed on the floor and walls. If it is planned to manufacture a cell battery, then the frame of the lower row structure is equipped with legs or wheels for transportation.

When the frame is ready, proceed to the arrangement of the floor. If you look at the drawing, you can see that it consists of two shelves. The lower part of the floor is intended for the installation of a pallet. This shelf is attached to the frame strictly horizontally. The upper floor is made at an angle 9о towards the egg box. Chickens will walk along this shelf, and the slope is needed to roll eggs. The upper floor should protrude beyond the boundaries of the front wall by 15 cm. Here, the edge is equipped with a side to form an egg collector. A gap of 12 cm is left between the upper and lower shelves to accommodate the pallet.

When the floor is ready, a fine-mesh mesh is attached to the frame on the ceiling, back and side walls. In front, the frame is sewn up with a coarse mesh. This can be done in two ways:

- On a narrow cage, the front wall is made fully hinged.

- If the width of the structure is more than 1 m, the front wall is thoroughly fixed to the frame, and a doorway is cut in a convenient place. The door to the wall is also hinged.

In single-tier structures, the ceiling mesh can also be made removable. Then it will be easier for the poultry farmer to pull the chickens through the top.

Feeders are bent from sheet steel. They are hung on the front wall so that the chicken can freely reach the feed. Pallets are equipped with sides so that the litter does not spill out when they are removed. For drinking bowls, it is better to use a nipple device, since the possibility of spilling excess water is excluded.

The video talks about making cells with your own hands:

Conclusion

This completes the cell manufacturing process. If chickens are supposed to be taken outside in the summer, each structure is equipped with a waterproof roof made of linoleum or other similar material.