Contents

There are no wine appellations in Normandy. The climate in the region is too cool and humid for growing grapes. But it is ideal for apples and pears, from which, since the French Revolution, cider has been distilled into a fragrant distillate, Calvados. And in this material, we tried to accumulate all the experience that helps Normandy distillers prepare the best apple brandy in the world, as well as translate the knowledge gained into a simple and understandable recipe.

Calvados (French: calvados) is a French apple brandy (although it may also contain pears) that is made by distilling cider. This is a strictly regional product, and its name is a symbol, meaning that this drink can only be produced in certain areas of northwestern France, in Lower Normandy. It also means that homemade apple brandy will not be called Calvados. But who cares about that, right?

In any case, if you make distillates from apples at home, then you need to do it the way it has been prepared in Normandy from generation to generation. And for this you need to conduct a little investigation, which we will do first. The time-honored cider apple brandy recipe is included.

Anatomy of Calvados – from apple to barrel

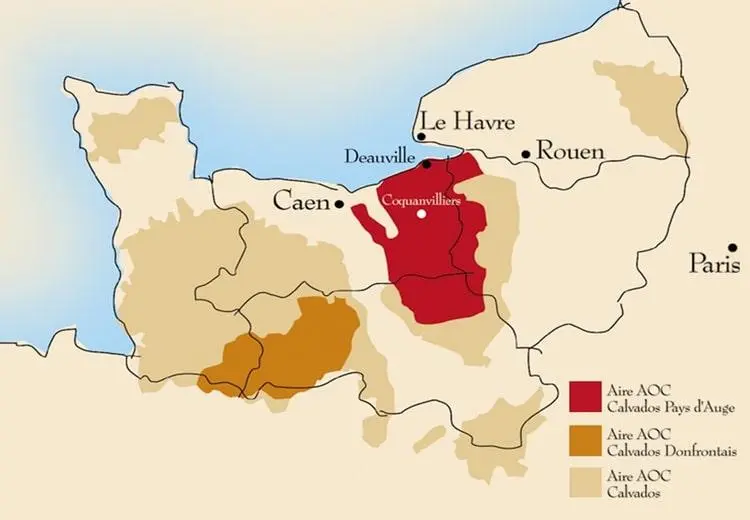

The production of Normandy apple brandy has been regulated by the Appellation d’Origine Contrôlée (AOC) since 1942. Like Cognac or Armagnac, the region that produces authentic Calvados is divided into three smaller sub-regions (there were ten until 1984), each with its own AOC. These are the appeals:

- AOC Calvados (about 74% of the total production of Calvados). Includes the departments of Calvados, Manche, Orne and parts of the departments of Ayr, Mayenne, Sarthe et Ayr and Loire.

- terroir, geographical area, strictly limited;

- varieties of apples and pears are determined by the style of the cider;

- spirits must be aged in oak barrels for at least 2 years;

- basic processes such as pressing, fermentation, distillation and aging are also regulated by the relevant state body;

- both double distillation in copper alambiks and single distillation in column-type apparatuses are allowed.

- AOC Calvados Pays d’Auge (25% of Calvados production). Bounded by the eastern end of the department of Calvados and several adjacent areas.

- all AOC Calvados requirements apply with additional restrictions;

- only double distillation in copper alambicas – columns are prohibited;

- the distillate must be made within the designated area in the Pays d’Auge;

- cider must be fermented for at least six weeks, and all the requirements of the Pays d’Auge region are imposed on its production (the cider here has its own AOC Pays d’Auge).

- AOC Calvados Domfrontais (about 1% of Calvados production). A small industrial area around the city of Domfront in the department of Orne, which received AOC status only in 1997.

- at least 30% of alcohols must be made from perry, pear cider;

- at least 3 years of aging in oak barrels;

- orchards from which the cider crop is taken must have at least 15% pear trees (25% from the 16th harvest);

- both double distillation in copper alambiks and single distillation in column-type apparatuses are allowed.

Apple brandy produced in France, but outside the Appellation d’Origine Contrôlée Calvados (or on its territory, but without due state control), is often called the slang calva (fr. calva). This has been going on since the first half of the 20th century, when there were about 15000 Calvados producers in Normandy, mostly unlicensed. They were mostly farmers who prepared apple moonshine for personal consumption. It was often peasant-style, simple and crude, and the main way to consume it is “cafés calva”, hot coffee with calvados.

Currently in the Calvados region, with an area of about 5400 km2, just over 300 manufacturers, mostly large ones, are registered. However, in Normandy, the tradition of producing farm Calvados has been preserved. If you see “Produit Fermier” or “Production Fermière” written on a bottle of apple brandy, then all the fruits for its production were grown on the same estate where cider was made from them, and then it was distilled and aged there.

Well, let’s play Normandy farmers and prepare a calva worthy of their approval?

Apples for Calvados

In the production of Normandy brandy, more than 200 different varieties of apples are used, which are traditionally divided into four types: bitter, bittersweet, sour and sweet. Pears are usually equated with sour apples, since only sour varieties of them are used (for example, Plant de Blanc). Distillates with them are softer and more tender. At AOC Calvados Domfrontais, Calvados cider must be at least 30% pear, although many producers use 70% or more.

Calvados is never made from one variety of apples – only their blend can guarantee a stable quality from year to year and a rich, complex taste of the distillate.

The most valuable apples are bitter and bittersweet varieties, such as Antoinette, Frequin Rouge, Bisquet, Moulin à Vent or Mettais. They bring to the cider the tannins necessary for the long-term aging of the cider, as well as the bulk of flavoring substances, Calvados acquires the necessary complexity and rich structure. Sweet varieties, such as Rouge Duret or Noël des Champs, are mainly needed to increase the alcohol yield, while sour varieties (Rambaud, Petit Jaune or René Martin) provide optimal acidity for cider fermentation.

Each manufacturer has its own proportions, as well as the varietal composition of the mash. Usually, the emphasis is on bitter and bittersweet varieties, which, for example, should be at least 70% in cider from AOC Pays d’Auge. A typical Calvados cider recipe might include 30% sweet, 40% sour and 30% bitter apples, sometimes 40%/20%/40%. Here we have to find a compromise, since we do not have specially bred varieties of apples and pears for brandy.

One thing is for sure: sweet apples like Fuji, Gala, Jonagold, Red Delicious and Golden Delicious won’t do anything good. Sweetness for a decent exit is better to bring sugar – squeeze up to 15 оP by hydrometer or 15 oBx on the refractometer at the start of fermentation can be safely, the distillate will not go into sugar fuselage. And if you use pure dextrose (glucose) or fructose, then manipulations with the product yield will generally go unnoticed. But this is already a matter of philosophy – if the number of apples allows, it is better to leave sugar for coffee.

But without fragrant apples, it’s impossible. You should try to take at least half of the juice from the available sour and most aromatic varieties (these are usually late autumn and winter apples), for example, from apples Idared, Antonovka, Granny Smith, Semerenko, etc. It will be even better if 20-30% of the usual game gets into the cider. At the same time, you can safely take a wild pear as a bitter base – this is the norm in Normandy.

Making cider

The fruits are harvested (manually or mechanically) from mid-October to December, let them mature in a cool place until fully ripe, crushed and pressed. Often, before pressing, the juice is allowed to brew on the pulp so that it extracts a maximum of extract substances from the skin. After pressing, the juice is fermented:

- using only wild yeast (it is forbidden to introduce a pure culture of yeast);

- using only fruit sugar (additionally add sugar is prohibited);

- at ambient temperatures (it is forbidden to artificially control the temperature, which is justified, because the process takes place at the end of autumn and the necessary slow fermentation is correlated with low temperatures outside).

Fermentation lasts from 1 to 3 months, with the production of dry cider with a strength of at least 4,5%, usually from 5 to 7%. The slowest fermentation is very important here – this way it ferments much more fruit esters and other “flavors”. To do this, low temperatures are maintained during fermentation, up to a maximum of 18оC, better 12-16оC.

Traditionally, cider is aged for up to a year in old barrels before being distilled, just in time for the new harvest. At the same time, it is not removed from the sediment. Here, look at your capabilities, it is better, of course, to withstand the cider for at least 4-6 months, during which it should be sufficiently clarified and gain complexity in taste.

But with wild yeast (hereinafter referred to as DD), I advise you not to indulge, only if you are going to cook cider not near an apple orchard in an environmentally friendly environment. Normandy farmers were lucky – in the production of air microflora was formed for centuries, there was a natural selection of yeast strains, DDs roam there cheerfully and pick up compounds that are extremely necessary for the taste and aroma of Calvados. On their side is the varietal composition of apple-pears, which provide ideal conditions for fermentation (the right acidity, the proper level of tannins, etc.). In our latitudes, DDs usually result in either sourness of the juice in the final stages of fermentation, or a slurred taste in the end, as the yeast has to work to the limit.

There are plenty of strains (pure yeast culture, PKD) for cider on the market right now (go to any brewer’s, vintner’s or moonshiner’s shop) – ideal. At worst, you can take any wine yeast for white wines or champagne. The main thing is not baker’s, which are suitable only for sugar mash, but even better for buns.

Approximately 1-650 liters of cider are obtained from 750 ton of apples. Just an interesting fact. In general, we have already written about cider and offered several of its recipes – the material is required reading!

Approximately 1-650 liters of cider are obtained from 750 ton of apples. Just an interesting fact. In general, we have already written about cider and offered several of its recipes – the material is required reading!

Mandatory reading and material on the manufacture of pear cider, perry, especially if you cook your Calvados with pears. There are a lot of nuances in their processing, for a successful outcome of the case, which must be taken into account.

Cider distillation

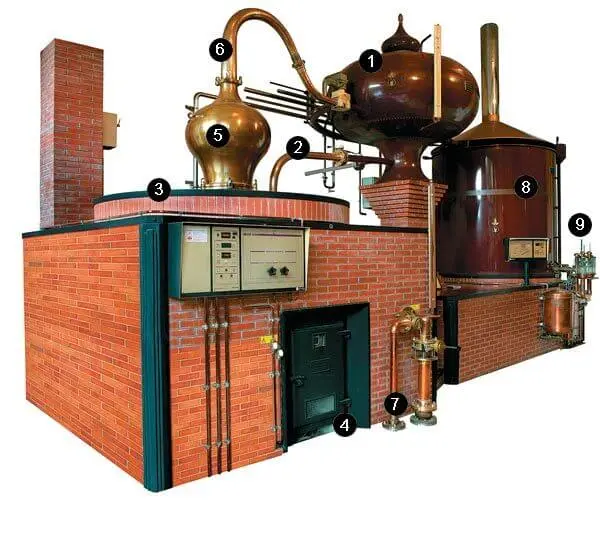

The best Calvados, and this is usually considered the brandy from AOC Calvados Pays d’Auge, is distilled twice in copper alambicas. Traditionally, these are Charente-type alambiks (fr. l’alambic à repasse or charentais), which are used to make cognac.

“Charente” distillation cube: 1 – a container for heating cider, 2 – a tube for supplying cider to the boiler, 3 – a heating boiler, 4 – a furnace, 5 – a “helmet” that accumulates distillate vapors, 6 – “swan neck”, 7 – drain pipe for “heads” and “tails”, 8 – coil, 9 – pipe for draining the finished product and an alcohol meter.

After the distillation of cider, raw alcohol (hereinafter referred to as SS) is obtained, which in France is called “brouillis” or “petites eaux” (low wine). Its strength is usually 28-30%. Often, during the first distillation, the “tails” are immediately cut off, and in some sources the cutting off of the “heads” is also mentioned. It is not recommended to do this at home, otherwise a lot of aroma is lost (remember the variety of raw materials for cider available to Normandy winemakers). It is possible to select only a small amount of the head fraction, literally up to a stable stream of SS – it will contain a lot of harmful isoamyl alcohol.

The second distillation is necessarily fractional, with careful cutting off of the head and tail fractions. Further work is carried out only with the “heart” of the distillate (“bonne chauffe”), the strength of which, according to the standard, should not exceed 72%.

In AOC Calvados and AOC Calvados Domfrontais, double distillation is rarely practiced. Cider is distilled only once, in column-type distillers. Traditionally, these are large tray columns, consisting of about 15 trays and selection units for each of the fractions. Single distillation is said to give Calvados a fresher, cleaner apple flavor, while double distillation is said to give the complexity needed for long barrel aging.

Calvados extract

After the distillation of cider comes the most important stage in the production of Calvados: aging. Apart from the mandatory two-year aging (three years for AOC Calvados Domfrontais), there are no other strict rules, so the methods differ dramatically from manufacturer to manufacturer. Exposure takes place in new or old barrels with a volume of 200 to 600 liters or in oak vats with a volume of up to 10000 liters. Alcohols aged in barrels and vats can be mixed.

Often “bonne chauffe” is poured into new barrels, from which the future Calvados takes over tannins and balances its aroma. These spirits are then poured into old barrels, where they absorb vanilla, toffee, hazelnut and chocolate flavors, gaining complexity and softening. In this, Calvados is very different from cognac and whiskey – it does not stand for years in one barrel, it is constantly poured and assembled (mixed with other aged spirits). Many leading manufacturers are experimenting with aging Calvados in whiskey, cognac, rum, sherry, port, etc. barrels.

After aging, alcohols are usually blended, mixed to obtain a homogeneous drink from year to year. Some distilleries, usually small farms, offer vintage bottles from a single barrel. After mixing, Calvados is diluted to 40-45% alcohol and bottled. Some brandies are bottled without dilution – over the long years of aging, the “angels” take up to 25-30% alcohol and they no longer need to be diluted.

Well, there is enough food for thought. How to interpret it let everyone decide for himself. For me personally, this all fits for some time into the recipe and technology described below.

Recipe for apple brandy with Calvados

We will prepare cider according to the “white” scheme, on pure apple juice without fermentation of the pulp, in which there is a lot of pectin, in our case, the precursor of methyl alcohol. The distillate will be cleaner, tastier and more aromatic. If for some reason you want to make apple moonshine according to the “red” scheme, we have a guide for such cases.

- mix of apples of different varieties

- sugar (dextrose or fructose) up to 15 оBx

- wine or cider yeast

Making cider

- After picking or buying apples, it is advisable to let them age in a cool, well-ventilated area for 2 to 4 weeks. During this time, they will ripen, become sweeter and more aromatic. Here it is important not to miss the moment and let them go for processing in time, since they give juice much worse when softened. Late autumn and winter varieties are always in favor – they have more juice and flavor, and the pulp does not become loose after maturing.

- After aging, apples must be thoroughly washed from dirt, even if fermentation is on DD (savages are not completely washed off with water, they are in the air and fermentation will still take place – checked). Then you need to extract juice from the fruits, which is usually done in two ways:

- Juicer. The juice comes out cloudy, which is bad for the fermentation and clarification of the cider. This is corrected by settling: the juice should be left in a cool place for 2-3 days, then removed from the sediment, the sediment filtered and yeast can be added. The performance of ordinary household juicers is small, you can immediately forget about serious volumes. Of course, there are more efficient centrifugal-type machines that allow processing up to 180 kg of fruits per hour, but their efficiency is only 50% – half of the juice remains in fine pulp, which is very difficult to press, and the squeezed juice is cloudy and requires clarification.

- Pressing. This method of obtaining juice is much better suited for our purposes, since it allows the juice to stand on the pulp for some time (cold maceration) to enrich it with aromatic extract substances. As a result, the juice is more fragrant and pure, and the cider is tasty and clarified in a timely manner. First you need to chop the apples (finely chop, use a wine crusher, grate on a coarse grater, pass through a meat grinder, etc.), and then slowly squeeze using a wine press (now you can buy it without any problems on the Internet or assemble it yourself according to the drawings from them ). Before pressing, we leave the juice for 6-8 hours in a cool place so that it gains taste and aroma from the pulp.

- Take a sample of juice to examine it for sugar and acid content. Add (optional) dextrose or fructose up to 15 оP by hydrometer or 15 oBx by refractometer. If necessary and desired, acidify the juice to pH 4 with malic or citric acid – the cider will turn out to be strong, capable of long-term aging.

- Pour the corrected juice into a clean, sterile fermenter, filling it with a maximum of ¾ of the total volume – there may be a lot of foam, or it may not be at all – it’s better to play it safe. Add yeast, cover the fermenter with a clean cloth and leave for 2-3 days in a dark, warm place until fermentation is gaining momentum (at the stage of reproduction, yeast needs oxygen and there is no need to install a water seal now).

- After 2-3 days, when the fermentation is already in full swing, install a water seal on the fermentation tank and transfer it to a dark cool (12-18оC) place until the end of fermentation. On DD, rapid fermentation can last at low temperatures for up to several months, CKD will eat the bulk of the sugar in 3-4 weeks (subject to low temperatures). Still striving for the slowest fermentation possible!

- After a couple of weeks of fermentation, the cider can be removed from the sediment, getting rid of the foam from pectin and calcium, which carbon dioxide pushed out of the juice to the surface of the container. Fermentation after this should slow down a bit, and the distillate after such a procedure is cleaner. In any case, when the water seal almost stops bubbling, a dense yeast sediment collects at the bottom of the fermenter, and the juice becomes a little lighter, you need to remove the mash from the sediment and send it under the water seal to a cool place. It is important to fill the fermenter to the very neck in order to minimize the contact of the wort with oxygen.

- Then wait as long as conditions allow. It is not necessary to remove the sediment – the taste will be richer. Ideally, in quiet fermentation and clarification, Calvados cider should spend at least until spring, after which it can be distilled without a twinge of conscience.

Distillation of cider for raw alcohol

So, we make our “petites eaux”, raw alcohol for obtaining ersatz calvados from it. There is nothing new here that may differ from the basic postulates of fractional distillation, I will not offer. Although there are a couple of important points. Main theses:

- it is necessary to distill cider as quickly as possible, with minimal boiling of yeast, it is better to distill directly with sediment – it is more fragrant;

- drive almost to dryness, at least up to 10% alcohol in the stream, but it can also go to zero, squeezing the fragrant distillate to the maximum;

- to reduce the content of methyl and isoamyl alcohol in the drink, you can cut off a few heads already during the first chase, according to organoleptics or until raw alcohol drips from the refrigerator, and does not run in a thin stream;

- the presence of copper in the steam zone of your moonshine will be a huge plus – apple brandy will turn out to be much tastier and more aromatic, as well as less harmful to health.

We have raw alcohol, ideally with a strength of 27-30%. If it turned out more, dilute to this fortress before the second distillation.

Second fractional distillation of calva

Copper in the steam zone is still highly desirable (alambique helmet, cymbals or column caps, tap changers). A very big job of cleaning raw alcohol from sulfur compounds, in particular, the most foul-smelling dimethyl trisulfide, is also carried out during the second distillation by a copper distillation cube (again, an alambik or an ordinary cube with copper plates inside). Copper before distillation, of course, must be well purified.

We carry out distillation slowly, with careful crushing of the shoulder strap into fractions:

- «head“and” head “cut off sparingly, since they contain a lot of fruit and flower aromatics valuable for Calvados – 5% of absolute alcohol in the SS or 1-1,5% of the SS volume will be a good guideline;

- «a heart» select up to 60-65% of alcohol in the stream without being greedy, changing the receiving container in time when fusel notes begin to appear in the smell;

- «tails» boost at your discretion (usually up to 10% alcohol in the stream) – they can be ringed, added to the next distillation of cider or raw apple alcohol, as you like.

And now we have “bonne chauffe”, a decent quality apple distillate, the strength of which, ideally, should not exceed 72%. Now, in order to get a thoroughbred kalva out of it, it needs to be ennobled with oak.

Aged apple brandy with Calvados

This is the time to arm yourself with the knowledge from the article on aging distillates in an oak barrel and refining them with oak chips. You can play the Normandy distiller, practicing multi-stage aging: first, a couple of months on wood chips, to enrich alcohols with tannins – imitations of a new barrel, and then in a barrel that has worked with another distillate, to smooth out all the roughness and shortcomings of distillation.

The main theses on the barrel:

- you can try barrels of any degree of roasting;

- you can, imitating the Norman moonshiners, first keep the distillate in a new barrel, and then pour it into the one that has already worked with bourbon, whiskey, rum, cognac or any wine, cider;

- you can fill in the “heart” without dilution, if its strength is not higher than 72%, otherwise dilute to this strength;

- the aging time is highly dependent on the volume of the barrel and is described in the article mentioned above – for 5-10 liters, 4 to 6 months are enough with regular sampling.

Steeping Oak Cubes in Pinot Noir

The main theses on wood chips:

- dilute the distillate to 45-55% before aging;

- you can try chips of any degree of roasting;

- previously, the chips can be soaked in a fragrant distillate or wine can be used for this (sherry, port wine – a classic);

- consumption for small chips and wood chips – 4 g / l or by eye, according to the experience of previous drinks;

- exposure 1-3 months, with periodic ventilation and sampling.

After refining the calva with oak, it must be filtered from wood dust, diluted to a drinking strength (40-45%) and poured into clean bottles. After bottling, the drink should be given at least 2-3 weeks of rest before tasting, but it is better to let it stand for 6 months or more – the taste will become richer and softer. If desired, our homemade Calvados can be tinted with sugar color, which is not prohibited either for Normandy or for most other fruit brandies.

Good luck!