Contents

For dry food, it is very convenient to use a bunker feeder model. The design consists of a grain container installed above the tray. As the bird eats, the feed is automatically poured from the hopper into the tray under its own weight. Such feeders are beneficial when fattening broilers for meat. The size of the bunker can be calculated so that the filled feed is enough for a day. To independently make a bunker feeder for chickens, you will need to build a pattern from several elements. In extreme cases, any container can be adapted under the bunker.

Why is it better to have a bunker feeder on the farm

When a poultry farmer first raises chickens, he usually puts their feed in a bowl or simply scatters it on the floor. The first option is not very convenient in terms of pollution. Litter, bedding material and other debris get into the feed. If the bird stands on the edge of the bowl, then it will turn over, and all the contents will be on the floor. The second feeding option is not suitable when using fine food. Instinctively, the chicken is constantly rowing in search of food, so she will eat most of the feed, but if we are talking about whole grains. Scattered compound feed is not always possible to get out of cracks and other hard-to-reach places on the floor. In addition, such food is simply trampled into the dirt.

By placing a bunker feeder in the chicken coop, the poultry farmer immediately solves several problems. Firstly, chickens will not be able to get their paws into the feed with all their desire. But at the same time, each bird is given free access to food. Second, the design is easy to maintain. This is especially felt when they put feeders for broilers, because this meat breed of chickens constantly eats. The bunker can be filled up once a day, and you will have to pour food into a regular bowl every hour.

Requirements for the parameters of the feeder

First, it is worth noting that any feeder that has a large capacity for the supply of feed is considered a bunker. Now let’s see what the requirements are for the design:

- The chicken should have free access to feed, and it should be easy to get it. At the same time, the bunker design simultaneously serves as a barrier for the bird so that it does not row in food. An important role on the tray is played by the sides. Their height should not allow food to spill onto the floor.

- The design of the bunker feeder is thought out to the smallest detail to make the product easier to use. They think of everything: material, fasteners, an opening lid and even a pedal with a feed dispenser. Usually feeders are made of plywood or plastic. A light product can be attached even to a cage, if it gets dirty, it can be quickly removed and washed.

- A very important requirement is the size of the feeder. If the capacity of the bunker is insufficient to provide food for the entire livestock, then servicing such a feeder is no different from a bowl. Compound feed will constantly have to be added to broilers. It is important to calculate the length correctly. The norm for 10 cm of a tray with food is 1 adult chicken. 5 cm of space is enough for a chicken. This does not mean that a two-meter structure will have to be made for 20 broilers. You can build two or four smaller feeders.

Near the tray with food should be enough space for all the chickens. Otherwise, weak birds will be repelled, and they will be severely stunted.

The video tells about the feeder:

Homemade feeder from plastic containers

Consider the manufacture of bunker models of feeders for broilers with our own hands, let’s start with the simplest design. You need to dig in the shed, and find any plastic container and tray. It can be a bucket with a lid, a thick sewer pipe, and other similar things.

An example of how to make a bunker-type feeder, we will consider on a bucket of water-based paint:

- So, there is a bucket of 10 liters with a lid. This will be the bunker. For the tray, you need to pick up any bowl larger than the diameter of the bucket. Better if it is also plastic.

- With a sharp knife, windows are cut out in a circle near the bottom of the bucket. Don’t make big holes. Enough holes with a diameter of 30–40 mm.

- The bucket is placed in a bowl, a through hole is drilled in the center of the bottom, after which the two elements are pulled together with a bolt. Although this action is not necessary, as the weight of the feed will firmly press the hopper against the tray.

Now it remains only to install the feeder in the chicken coop, pour a full bucket of feed and cover it with a lid.

Drawings, photos and the procedure for manufacturing a wooden bunker feeder

A reliable and complete feeder for chickens can be made of wood. Only the board for this work is not the best choice. Sheet material is perfect: plywood, OSB or chipboard. We will connect the cut elements with slats and self-tapping screws.

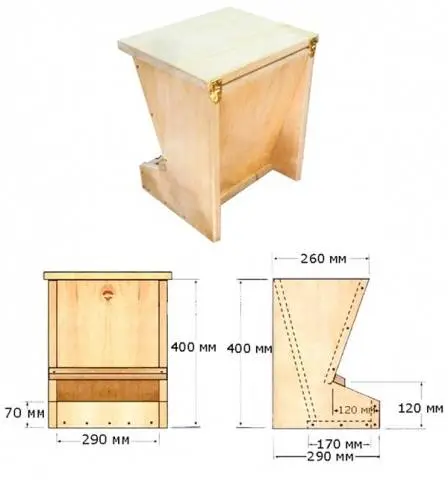

First you need to make a do-it-yourself drawing of a bunker feeder for chickens, according to which the sheet material will be cut. The photo shows a diagram. You can leave these dimensions or calculate your own by adjusting the dimensions of the structure to the number of chickens.

The diagram shows that the structure consists of two identical side parts, the front and rear walls, forming a bunker. The lid is hinged on top. The bottom of the side parts and the back wall form a tray. It remains only to carve out the front element – the side, as well as the bottom. The result should be a bunker structure, such as shown in the photo.

If desired, the drawing can be modified. The sides are cut out in a V-shape, and the tray is extended to two sides of the hopper, and made as a separate box. The result is a double-sided bunker feeder.

The principle of manufacturing a bunker structure is simple:

- on the selected sheet material, all the details of the pattern are drawn;

- the drawn fragments are cut out with a jigsaw;

- the edges of the workpieces are ground with fine-grained sandpaper;

- with a thin drill, through holes for bolts or small recesses for self-tapping screws are made;

- installing rails for reinforcement at the connecting joints, assemble the entire structure, tightening it with bolts or self-tapping screws;

- the lid of the hopper is hinged so that it can be opened.

Feed is poured inside the finished bunker, and the feeder can be placed in the barn for chickens.

Improvement of the feeder with a pedal with a dispenser

The hopper-type feeder, improved with a dispenser, was invented by a farmer from Australia. The design is intended for feeding a small number of chickens. If necessary, it is better to make them larger, but do not increase the size in any way. Otherwise, the dispenser mechanism will not work.

The principle of operation of the design is simple. A wide pedal is installed in front of the plywood tray. It is connected with the lid of the tray by rods made of wooden slats. When the chicken gets on the pedal, it goes down. At this time, the rods raise the lid of the tray where the feed is poured. When the chicken comes off the pedal, the lid will cover the tray again.

A self-made tree feeder will last longer if it is impregnated with a protective antiseptic. It is undesirable to use varnishes and paints, as they can harm the health of chickens.