For several years now, the hype around the Chinese miracle yeast koji, which has earned a reputation as a cure for fear of grain jams, has not subsided. Many have given up labor-intensive and complex procedures associated with the use of malt, replacing them with the simplest technology of cold saccharification with sourdough TM “Angel”. But is it really so simple and what is really hidden under the Japanese term “koji”? Let’s figure it out!

In the traditional sense, koji (from English “koji” or Japanese “麹”) is a kind of substrate, usually steamed rice or soybeans, on the surface of which a colony of the mold Aspergillus oryzae is grown. From about the 300s. BC. such substrates were used in China and later throughout Asia for the preparation of various fermented foods such as soy sauce, miso, douchi, etc. Alcoholic beverages were also included: in China, starters based on mold and yeast, known as “qu”, have been used for centuries to make the national baijiu vodka, and in Japan, koji, for sake and shochu.

During growth, A. oryzae produces a large number of amylotic enzymes (mainly α-amylase and glucoamylase), which break down starch into sugar with high efficiency, thus allowing normal yeast to ferment starchy foods. In other words, mold spores, called koji-kin or tane-koji, play the role of malt here, only in addition to enzymes that break down carbohydrates, they also produce enzymes that target proteins. New amino acids are formed, with a “high” umami taste, as well as mushroom, cheesy and subtle fruit undertones characteristic of sake.

This is what koji looks like on steamed rice.

Growing a real koji is quite troublesome, even more difficult to get a real koji-kin. And here the Chinese come into play, who a few years ago offered the whole world a certain version of a universal sourdough, later erroneously called koji yeast in the CIS. It has nothing to do with Japanese mold, but is damn good at dealing with grain mashes.

Chinese koji yeast is a complex starter culture for cold saccharification and fermentation of any raw materials containing starch. Further we will consider this phenomenon exclusively on the example of TM “Angel” yeast, since at the moment these are the only “koji” widely represented in the CIS markets. What exactly and in what quantities is included in the products of TM “Angel” under the code name “Leaven” we can only guess. The main thing to remember is that they are distinguished from the rest of the yeast in the company’s line (and there are beer, wine, and ordinary alcohol ones) by a yellow square on the package.

The manufacturer gives the following composition: alcohol yeast (presumably with complex feeding), amylotic enzymes (alpha-amylase, beta-amylase, phytase), as well as a certain “rhizopus”. It is difficult to say what the last term means. It does not appear to be live Rhizopus oryzae mold spores or a “live” substrate treated by them, otherwise it would be difficult to transport the yeast across borders. And the koji themselves, as we found out, work a little differently. Perhaps the manufacturer is evasively pointing to fungal enzymes that can be found among the products of TM “Angel” (for example, fungal α-amylase obtained using Aspergillus oryzae).

But it’s all poetry. In practice, we have a kind of universal tool that allows us to cook grain mash with minimal effort. An option for the lazy and patient, because after the simplest mash preparation procedure, you will have to wait about 3 weeks until the mash ferments to dryness (but there are tricks that allow you to ferment the mash in an incredible 4 days). Not a big price to pay for saving the strength and nerves spent on saccharification with malt. But this is already a matter of philosophy – to achieve the same organoleptics as with malt, with Chinese miracle yeast it will not work, no matter how hard you try.

In addition to long fermentation, koji have almost no drawbacks, especially if they are considered not as an alternative to malt, but as a separate technology for producing mash from starchy raw materials (such as enzymes). Moonshine with Chinese yeast turns out to be tasty, soft, balanced and has all the distinctive features characteristic of grain distillates. The effectiveness of the sourdough deserves special praise – the output is colossal!

Safety precautions! Like any food product, koji undergo mandatory certification and are considered completely safe for health. However, it should be remembered that the enzymes that make up the composition, as well as this mystical “rhizopus”, are usually of a fungal origin, so no one will blame you for being too careful. Wear gloves, wear a mask and be sure to stay away from food. Keeping away from children and in an airtight condition will be taken for granted.

Preparing for koji

So, you’ve made up your mind. We bought a pound of Chinese miracle yeast at a local store or ordered it on AliExpress (here is an affiliate link for two packs of yeast at a very reasonable price), you have a fermentation tank of the right volume and some kind of moonshine still. What’s next? Theory!

- Raw materials. In fact, you can use any raw material containing starch, even potatoes, but only grains are tasty. Time-tested cereals from wheat (“Poltava No. 1-4”, “Artek”, semolina, chopped), corn (crushed and polished No. 1-5), barley (barley, barley), millet (grinded and crushed), buckwheat, rye and oats. Accordingly, it is possible to ferment flour of different grinding and pure starch from these cereals. Mixing of different types of raw materials is allowed, for example, rice and wheat, corn and barley, barley and rye. It is better to read about such blends in materials about bourbon or whiskey.

- Grinding. The thinner it is, the faster the enzymes will break down the starch and the faster the yeast will ferment the resulting sugars. There is another side to the coin – it is difficult to stir flour due to clumping, saccharification may be incomplete. Choose a grind based on your experience and available equipment. Rice and buckwheat can be fermented whole, but the timing will be appropriate.

- Preparation of raw materials. Any heat treatment of grain will speed up fermentation. Well-steamed or boiled raw materials can be fermented in 4 days, while crushed stone filled with warm water can ferment for more than 3 weeks. If you don’t want to bother with cooking, just pour boiling water over the cereal and wait for it to cool before adding yeast – save a week or two.

- dosage. The manufacturer recommends using 3-8 g of yeast per 1 kg of grain, depending on the degree of pre-treatment of the raw materials and various fermentation schemes. In practice, these proportions are slightly underestimated and often lead to mischief. The optimal weight for koji is 8-9 g/kg. The weight of yeast, the expiration date of which is coming to an end, should be increased by 1-2 g/kg. Reducing the dosage correlates with an increase in fermentation time.

- Hydromodule. The manufacturer recommends adding 1-2,5 liters of water for every 3 kg of grain, and these proportions have never failed. An increase in the hydro-modulus reduces the fermentation time and reduces the formation of foreign impurities, but more yeast will also need to be added. Optimal 8-9 g/kg koji performed well with a standard GM of 1/2,5-1/4.

Armed with knowledge, it’s time to kick out the moonshine. Let’s take a typical, basic recipe that is applicable to almost any type of raw material, and describe the basic technology for working with koji. Well, then just experiment, experiment and experiment again! For example, you can try using roasted barley to add smoky flavors to the distillate, or, say, adding some aromatic ingredients to the fermenter at the final stage of fermentation, as in genever.

Universal koji mash recipe

- 10 kg of grain flour or cereals

- 80-90g koji yeast (8-9g/kg)

- 30-40 l of clean, not boiled water (3-4 l/kg)

Braga preparation technology:

- Thoroughly wash the fermentation tank, hands and any tools that will come into contact with the mash, any disinfectant (for example, a solution of potassium metabisulphite). Sterility is an important part of successfully making koji moonshine, as fermentation will be slow and grain mashes are very susceptible to bacterial contamination. We don’t cheat!

- Prepare raw materials: pour flour or cereals into a fermenter from food materials, pour boiling water over everything and wait for cooling to +28..+30 оC. This procedure can be skipped by using ordinary warm water instead of boiling water (+28..+30 оC) water. Remember that any preliminary heat treatment of raw materials will significantly speed up the fermentation process.

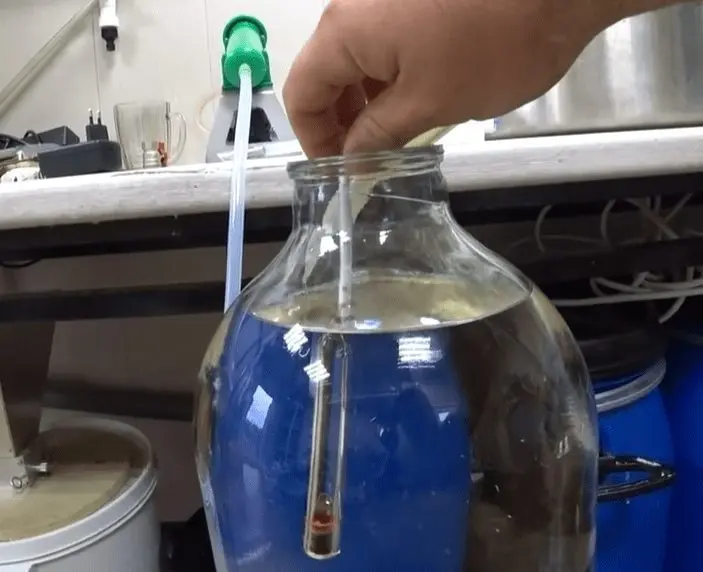

- Rehydrate yeast: take the required amount of koji and pour it into ten times the volume of warm (+32..+35 оC) water. Wait 15 minutes and pour the starter into a fermentation tank with a cooled “porridge”.

Important! The temperature difference between starter and mash should not exceed 10 оC, otherwise the yeast may die. However, as practice has shown, Chinese koji endure a lot – both addition without rehydration, and high temperatures (up to +55 оC) and other troubles. Such strong Asian hard workers. But this does not mean that from inept or inattentive handling of them one day you will not receive ill will.

- After introducing the starter, install a water seal on the container and leave it in a dark, warm place until the end of fermentation. The ideal fermentation temperature for Chinese koji is +32 оС, operating range — +28..+36 оC. Lower temperature leads to an increase in fermentation time, and prolonged high temperature (above +38 оC) can cause it to completely stop.

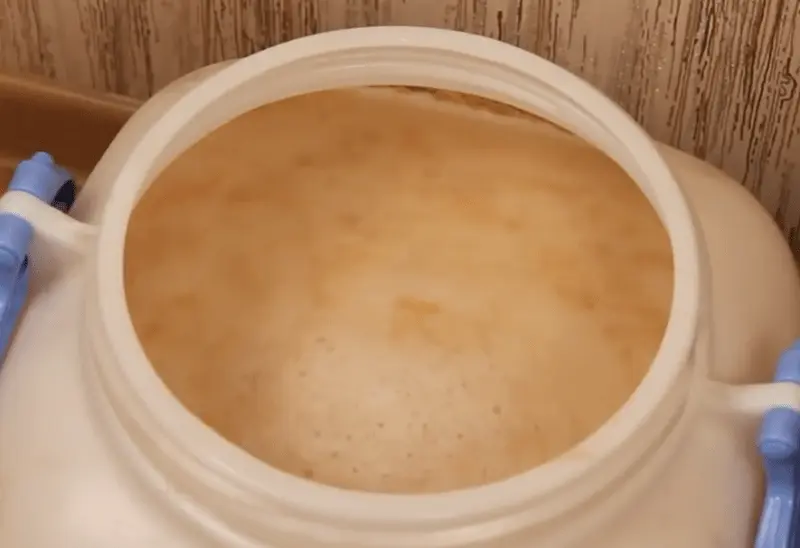

About defoamers. Braga on Chinese yeast can foam a lot, which is usually more pronounced when working with raw materials without any heat treatment. This must be taken into account when choosing a fermentation tank and proportioning the mash, leaving enough space in the fermenter (at least 6-10 cm, and preferably a quarter of a tank) for foam. Or you can just use a Sofexil defoamer.

- Yeast starts fairly quickly, usually 3-5 hours after being introduced into the mash. During the first 3-4 days, the mash must be stirred at least twice a day. This is necessary for the complete saccharification of raw materials (cereals and flour are clumped, enzymes do not get access to starch) and degassing. Mixing can be done by tilting the fermenter or by briefly opening the container with a sterile spatula or hand. Be sure to observe sanitation!

About antibiotics. Many moonshiners add antibiotics to koji mash, mainly Dosycycline, Amoxiclav, Ceftriaxone, etc. I do not encourage such practices and see in them the approach of modern-archaic medicine, when diseases heal, and do not try to eliminate the root cause. Maintaining sanitation during the preparation and fermentation of the mash is enough to prevent infection. It is better to show self-organization and attentiveness to the process.

- Depending on the primary processing of raw materials, its type, temperature and other factors, fermentation can last from 4 days to 3 weeks. The readiness will be indicated by the absence of bubbling in the hydraulic seal and the clarification of the upper part of the mash with the precipitation of a dense sediment. Braga itself will taste bitter and sour (but I don’t recommend trying it – the same “rhizopus” in the composition still confuses me).

About the smell. Sometimes koji mash exudes not the most pleasant smell, with rotten. This does not always happen and largely depends on the type and quality of raw materials. For example, congestion in the cell is often accompanied by a nauseating smell. Definitely, you should not be afraid of this phenomenon, just the specifics of the sourdough, and all unpleasant aromas will be 100% removed by double distillation.

So, the mash is ready and you can start distillation. There is nothing here that could distinguish this procedure from the basic postulates of double fractional distillation (adepts of rectification will figure it out themselves). But there are a couple of important points to mention.

Distillation of brew on Koji yeast

- It can be distilled on the lees, directly with grains, which is believed to improve the organoleptics of the drink and slightly increase the yield. Since the saccharification on koji is carried out as completely as possible, the risk of pellet burning is minimal, but there have been precedents. For safety net, the grains can be filtered (with the loss of some alcohol) or a false bottom / nylon filter bag can be used.

- Distill Braga as quickly as possible, up to 10% in the stream, do not crush. Copper elements in the steam zone of the moonshine will improve the organoleptics and reduce the content of sulfur compounds in raw alcohol (hereinafter referred to as SS). For grain moonshine on koji, you can also use Gabriel distillation (crushing already at the first distillation), which is especially important during the subsequent aging of the distillate in an oak barrel and when using direct-flow devices.

- Next, dilute the SS to 18-20% and distill fractionally – nothing new. Heads are usually advised to select more, but the standard for cereals 5-8% of absolute alcohol in SS is usually more than enough. Here you should focus on the smell and experience with existing equipment. The body to select up to 50-60% alcohol in the jet, without being greedy. If under the barrel, cut off the tails in a sparing mode.

What can be said about the exit? It is really impressive, especially for rice – under ideal conditions, you can squeeze a maximum of 425-450 ml of absolute alcohol from 1 kg. Much depends on the quality of raw materials, the technology of making mash and distillation. A good yield is 350-400 ml per 1 kg for almost all grains, less than 300-350 ml is bad, unkind.

Further manipulations with the finished product depend on your personal preferences, experience and the raw materials used. Rice and wheat distillates, which are characterized by a neutral flavor profile, can be further carbonated, diluted to drinking strength and tasted after a couple of weeks. It makes sense to keep moonshine from corn or barley in a barrel or on oak chips – worthy imitations of bourbon and whiskey, respectively, are obtained, although not so fragrant.

Instead of deducing

Obviously, Chinese koji yeast cannot be a full-fledged replacement for malt in the context of making first-class grain distillates. But the simplest technology, a decent yield and a pleasant organoleptic result make them ideal for beginners in moonshine brewing, who have already mastered sugar mash, but are not yet ready for temperature pauses, iodine tests, the fight against pellets, burning, and all that. We approve!

What is your experience with koji? Do you approve?