Contents

In this article we will tell you how to independently repair Bosch washing machines (Bosch). Learn how to fix minor and moderate damage without resorting to the services of a master.

Bosch washing machines attract attention and deserve the respect of buyers due to their high quality and abundance of innovative technologies. The German assembly fully justifies the price of such washing machines – high-quality materials are used in the manufacture, and the developers prefer ergonomic shapes. But even among the highest quality equipment, breakdowns are not ruled out.

Bosch breakdown diagnostics

Bosch washing machine diagnostics is a built-in function in all modern machines. Thanks to it, you can determine the essence of the breakdown without calling the workshop. If you did not find in the instructions a step-by-step description of how to carry out diagnostics yourself, we will describe in detail how to do this:

- Close the loading door.

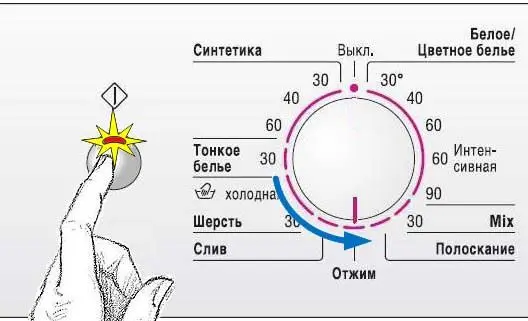

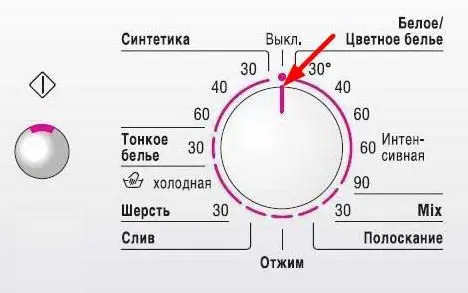

- Set the program selection wheel to “OFF”.

- Wait a couple of seconds.

- Set the mode selector to «SPIN».

- If you have done everything correctly, the “START” light will flash.

- Press the “SPIN RPM” button and do not remove your finger until the “START” indicator flashes again.

- Turn the wheel again, this time stopping it on the DRAIN program.

Attention! Rotate the selector only to the right.

- After releasing the “SPIN RPM” button, select the object to be tested by turning the wheel. Or determine the breakdown by the error code displayed on the scoreboard.

Important! If the diagnostics do not start, then the problem is in the control board (electronic controller), and in this case, you cannot do without calling the wizard.

If you decide to manually check individual parts, turn the selector wheel to select the desired item. Proceed like this:

- Engine check: position 3.

- 4 – for testing the pump.

- 5 – check the heating element.

- 6 – hot water intake valve.

- 7 – cold water intake valve.

- 8 – water intake valve for the main wash.

- 9 – pre-wash water intake valve.

- 10 – sound signals.

- 11 — self test FCW.

- 14-15 – “quick” autotest.

Next, press “START” again (in addition to this indicator, “DRAIN” and “SPIN” are also lit) to start the program test.

To exit the program test mode, press START and turn the wheel.

To exit diagnostic mode, turn the wheel to “OFF” or “OFF”.

Typical breakdowns of Bosch machines

Of the entire huge list of malfunctions of the Bosch washing machine, the most typical for this brand are the following failures:

- When washing, the water does not heat up.

- No plum.

- The tank is not spinning.

- The drum is noisy.

- There is no water intake.

- The engine doesn’t work.

Based on the specified list, we come to the conclusion that the most vulnerable spot of the washers of this brand is the heating element. If the thermoelectric heater burns out, but the controller is intact, then repairing the Bosch washing machine does not take much work and effort. Otherwise, you need to replace the controller, and this work is best left to a specialist.

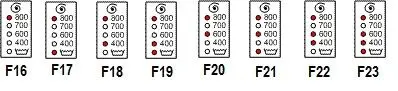

Users will learn about certain malfunctions by fault codes (or flashing lights). The following error codes usually appear in Bosch SM: F01, F16, F29, F31, F34, F36, F40, F61, F63, as well as E02 and E67 and others.

Causes of breakdowns

The device of the Bosch washing machine determines both the nature of the breakdowns and the causes of their occurrence. Consider what usually causes crashes.

After washing, waste water is in the tank. This happens for the following reasons:

- Failure of the drain pump (pump).

- Clogged filter or pump.

- Blown or oxidized pump contacts.

- The pressure switch broke.

If the drum is firmly stuck, this may be due to such reasons:

- Drive belt damaged.

- Electronics failure.

- Less often – engine failure.

Drum rumble is associated with:

- Broken bearings (you will need to replace the bearing in the Bosch washing machine).

- Rubbish and foreign objects in the tank.

- Loose or broken shock absorbers.

- Ripped counterweight.

Water does not enter the drum because:

- There is no water in the water supply system, low pressure.

- The pump or Aqua-Stop system is clogged.

- Drain hose kink.

Engine failure coincides with the following “symptoms”:

- Open hatch.

- Controller failure.

Having determined what caused the malfunction, and evaluating its complexity, you can start self-repairing Bosch washing machines.

If you have not identified a breakdown, and do not know how to repair a washing machine, contact a specialist.

The listed causes of breakdowns are most typical for Bosch Classic 5, Bosch Maxx 5, Bosch Max 4, Bosch Maxx 6 models, but other models may fail for the same reasons.

Doing your own Bosch car repairs

Below we will look at malfunctions and how to fix them, paying attention to the most common failures and the best ways to solve them.

We repair the drain pump and filter, the pressure switch of the Bosch machine

Having determined that a drain pump (pump), a drain filter or a water level sensor (pressure switch) needs repair, we carry out repairs ourselves – this does not require special knowledge and effort.

To eliminate clogging of the filter, we act according to the following scheme:

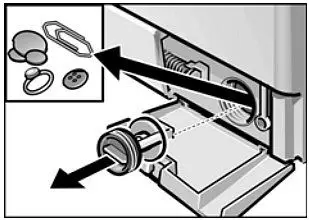

- Let’s find the drain filter: it is located at the bottom of the washer body, under the front panel (you can get to it from below by putting the machine on its side) or behind the door of a small technical hatch.

- It is necessary to lay a rag or substitute a container – the remaining waste water will gush out of the hole.

- Turning the filter cover to the left, remove it.

- We clean the filter and rinse it under the tap.

- We install in place. Remember that it is IMPOSSIBLE to run SM without a filter.

To clean or replace the drain pump (pump), you need to correctly remove the front panel; to do this, you may need the instructions for your brand Bosch washing machine. In principle, nothing complicated, but you need to make an effort.

- Take out the detergent drawer.

- Loosen the bolt in the lower right corner.

- Remove the bottom panel by unscrewing the bolt near the filter and the bolts at the bottom of the panel.

- Remove the rubber cuff of the hatch (to do this, remove the fixing ring by bending a small spring with a slotted (minus) screwdriver).

- Remove the panel.

To get close to the pump itself, remove the UBL wires. Remove and disassemble the pump – it may contain foreign objects and debris. The impeller in a working pump rotates easily in all directions.

Check the resistance of the pump winding. If it is 200 ohms – order. If the values are different, there is a breakdown, and the pump needs to be changed.

If water is not collected, you need:

- Check if the machine is connected to the water supply (if not, open the valve).

- Inspect the drain hose (it may have creases and kinks).

- Check the AQUA-STOP filter. If there are problems with it, you need to replace it with a new one.

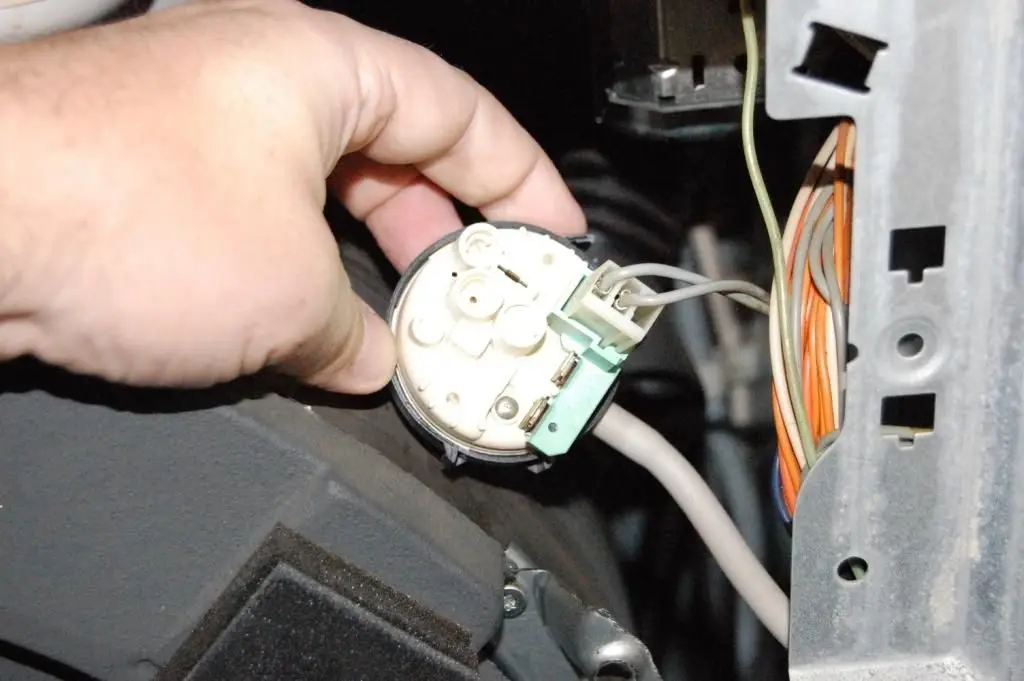

If the water level sensor breaks down, change it according to the following scenario:

- We find the sensor by removing the top cover of the car – you will see it in the right corner if you look at the car from the front. To remove the cover, twist 2 bolts.

- By pressing the latch, we remove the sensor. We remove the wires and disconnect the pipe by opening the clamp.

- We install the new unit in place of the old one, acting in the same way, but in reverse order.

Replacing the heating element with your own hands

If the heating element has worked out its resource or is overgrown with scale, overheated and burned out, you need to change it. This work can be done on your own. But first you need to check.

If you are not sure whether the heating element is working or broken, you can check it yourself, armed with a tester. The check is carried out as follows:

- Without removing the heating element, disconnect the wiring.

- Set the tester to the resistance measurement mode (in ohms).

- Set the governor wheel to “200”.

- Attach the probes to the terminals of the electric heater.

- Normal resistance usually ranges from 20 to 40 ohms.

- If the value of the tester is “1”, then a break has occurred, and the heating element needs to be changed.

- If the value is near “0”, there is a short circuit in the heating element, the heater needs to be changed.

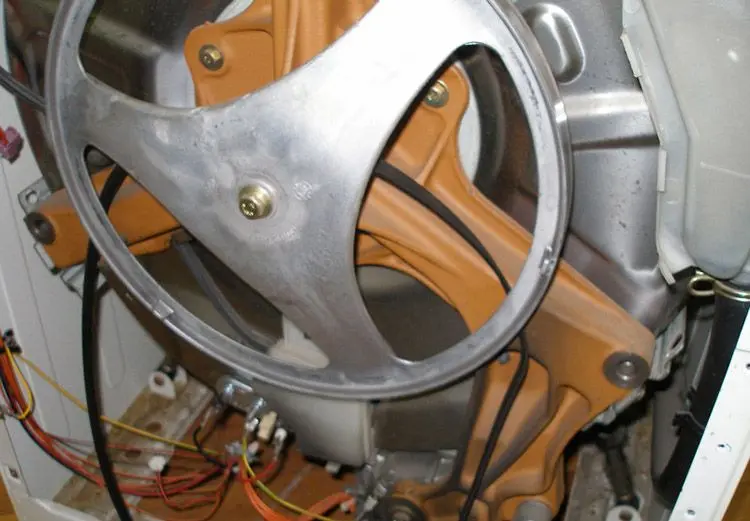

Finding the heating element is simple: remove the back panel of the SMA and below the drum you will see the heating element, or rather its shank, with a screw driven in the center. We make a replacement:

- Loosen the bolt.

- Remove all wires carefully.

- Remove the heater by slowly loosening it from side to side and pulling it towards you.

- Take a working heating element and install it.

Self-replacement of bearings

To carry out this complex operation, almost complete disassembly of the SM is needed. If you decide to do this, do not completely remove all the wires from the electronic module – it is not a fact that you will be able to connect everything in place. After dismantling the module, lay it on the frame or hang it on a special hook.

We make a technological hook

To make a technological hook with your own hands, take a 30-centimeter piece of non-hardened steel wire with a diameter of 3 mm or more. A cambric (heat shrink) should be strung on the wire, which should be longer than the wire – at least 1 cm on each side. Make bends, stepping back from each end of the wire 6-7 cm – you will get a kind of hook. Hang the dashboard on this hook.

We continue to disassemble the car

- We remove the tank with the drum by unscrewing the springs.

- When disassembling the tank into 2 parts, the specially provided latches must be broken.

- Using a hammer and a piece of wood, carefully knock out the bearing axles with light blows.

When choosing new bearings, make sure that the parts match your brand of washer. For example, you need bearings for a Bosch Max 5 washing machine – say so in the store so as not to buy the wrong parts.

The video shows how the master disassembles the Bosch machine and changes the bearing. See if you need this:

As you can see, do-it-yourself Bosch washing machine repair is a doable task. Just remember to periodically clean your washer and maintain it to keep it from breaking down.