Contents

Summer residents who have high beds on their site have long appreciated their dignity. The fencing of an earth embankment is most often equipped independently from improvised materials. The disadvantage of homemade boards is a short service life, unaesthetic appearance, lack of mobility. Another thing is if you install galvanized beds in the country for planting vegetables and flowers. Collapsible structures are easy to move to any place, and such boards will last for about 20 years without losing their aesthetic appearance.

Pros and cons of using galvanized metal fencing

It just so happens that building materials are increasingly beginning to be used for arranging summer cottages, in particular, vegetable gardens. Initially, earth embankments were fenced with slate, brick, cinder block or boards. Now it’s the turn of the professional sheet. The fact is that store metal beds are made of the same material as corrugated board.

Let’s see what is more profitable than a galvanized factory fence from home-made boards:

- metal is a material not suitable for the life of fungi and other garden pests, which is especially important for a greenhouse;

- all store beds made of galvanized metal are a collapsible structure that can be quickly assembled or disassembled when moving to another place;

- galvanized fencing, if necessary, can be made longer or increase the sides in height;

- a small mass of the sides allows you to independently assemble and carry the box without outside help;

- many store beds made of galvanized steel are made in such a way that they can be folded into an original polygonal fence;

- galvanized with polymer coating has all the shades of the color of the corrugated board, which allows you to decorate the summer cottage to your taste;

- ordinary beds made of galvanized metal will last up to 20 years, and if a polymer coating is applied on top, the service life will increase to 30 years;

- it is convenient to attach arcs under the greenhouse and drip irrigation pipe to the galvanized fence.

However, everything cannot be perfect, and metal fences similarly have a number of disadvantages. The first one is the high cost of the finished product. The second disadvantage is the high thermal conductivity of the metal. Although this shortcoming must be dealt with. The metal quickly warms up in the sun, causing the root system of plants to suffer. Root crops growing near the side, in general, disappear. This problem is more typical for the southern regions, where metal beds are not the best type of fencing. For cold areas, the rapid heating of metal sides can be considered a plus. In early spring, the soil in the box will become warm faster, and if you additionally stretch a greenhouse over the bed, you can grow early vegetables.

Variety of galvanized railings

So, fences for beds are made from the same material as corrugated board. Hence, the products are divided into the following types:

- Ordinary silver-colored galvanized beds are made of sheet steel. Only a layer of zinc is applied as a protective coating.

- Beds with a polymer coating, produced in different colors, have additional protection. The sides of the product are made of sheet steel. As a protection, the first layer of zinc is applied to the metal, and the second layer is a polymer.

- Iron fences for beds, treated with polyurethane coating, are made by analogy with polymer-coated products. The boards are produced in different colors from the same galvanized sheet steel, only a layer of polyurethane is applied instead of a polymer.

The galvanized coating serves as the main protection of the metal against corrosion. The service life of the garden fence increases several times. However, zinc itself can be endangered if, for example, it enters an acidic environment. Additional protection is provided by a polymer layer at least 25 microns thick applied over zinc. The service life of a polymer bed in comparison with a galvanized product increases by another 2-3 times. The polymer does not react with any kind of fertilizer, soil and water.

On the video you can see galvanized beds:

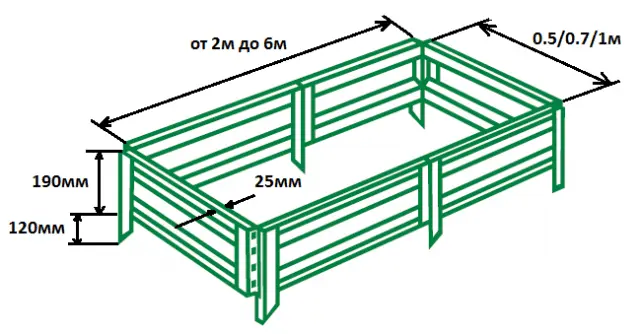

Fences for earthen embankments are produced from galvanized steel with a polymer coating of various sizes. Boxes with a width of 50 and 36 cm are in the greatest demand. I make the design of the border for the flower bed in such a way that it can be given any length by adding or subtracting sections. Very easy to use galvanized beds, with the possibility of increasing the sides. This happens by similarly adding sections only in height.

As for the beds with a polymer coating, the manufacturing technology of the metal sheet itself is much more complicated. Hence the high cost, but also a longer service life.

The material used in the manufacture of polymer-coated boards has the following characteristics:

- sheet steel is taken as the basis;

- both sides of the sheet are coated with zinc;

- the second is the passivating layer;

- the third coating is a primer;

- the back side of the sheet is covered with a layer of paint;

- the front side of the sheet is covered with a colored polymer.

The most reliable is the polyurethane coating. The top colored layer of the fence is resistant to UV rays, corrosion and weak mechanical stress. Putting a scratch on such a board is very difficult. The service life of a fence with a polyurethane coating reaches 50 years, but the high cost does not make the product popular among summer residents.

The cost of metal fences

The price of galvanized steel beds is formed taking into account many factors. First, the protective layer is taken into account. The cheapest will be metal boxes with a galvanized coating, and the most expensive ones with a polyurethane layer. The golden mean in terms of cost are polymer-coated fences. Secondly, the price is formed by the size of the box and the number of collapsible elements.

A standard rectangular metal box consists of two end and side shelves. They are connected to each other with fasteners. The fence is sold as a set, and the price is set for the entire product.

Large galvanized beds have the property of bending the side walls with soil pressure. To avoid this, steel extensions included in the package of such products allow. There are models of fences that allow building up the sides. Such products are sold as standard, and additional boards can be purchased separately.

Factory fencing assembly

Assembling prefabricated polymer-coated metal beds is so easy that you don’t even have to look at the included instructions. If the assembly is being performed for the first time, it is better to look at the drawing. The easiest way is to collect a bed made according to the French system. Here, the simplest latches act as fasteners, with the help of which they connect all the elements. Due to the upgraded latches, the cost of the entire fence increases.

It is more difficult to assemble a fence, the sides of which are bolted or self-tapping. Such beds are produced in rectangular and polygonal shapes. In terms of quick assembly and disassembly, the boxes are unprofitable, but the cost of products is much lower than that of the analogue according to the French system.

A standard galvanized bed can be assembled in 30 minutes. It is enough to connect four sides into a rectangular fence.

The video shows metal boxes with a polymer coating:

Do-it-yourself galvanized bed

If desired, a metal bed can be made independently. For the sides you will need galvanized sheet or corrugated board. The main issue is the manufacture of the frame. You will need four corner posts and eight crossbeams. The frame is welded from a metal corner or assembled from a wooden bar. Fragments are cut out of galvanized sheet or corrugated board according to the size of the sides, and fixed with self-tapping screws to the frame.

When making a homemade garden bed, it is important to protect the edges of the fence from burrs. On a metal frame, the sharp edge of the galvanized sheet will hide under the horizontal shelf of the corner. On a wooden frame, the place of fixation of the sharp edge of galvanization is hidden under the casing.

Reviews of summer residents about metal beds

Often, user reviews on the forum help determine the purchase. Let’s find out what people say about metal beds.