Contents

Housekeeping takes a lot of time and effort from the owner. Even if there are only chickens in the barn, they need to change the bedding, build nests, and, most importantly, feed them on time. It is unprofitable to use primitive bowl or box feeders, as most of the feed is scattered on the floor and mixed with droppings. Store-bought bird feeders are expensive. In this situation, the poultry farmer will be helped out by an automatic feeder for chickens, which you can assemble yourself in a couple of hours.

Automatic feeder device

Automatic feeders come in a wide variety of designs, but they all work on the same principle: feed is automatically added to the tray from the hopper as it is eaten by the hens. The advantage of such a device lies in the constant provision of food to the bird, as long as it is present in the container. The bunker is very convenient because it can contain a large supply of feed. Let’s say that the daily norm of food will save the owner from visiting the chicken coop with broilers every 2-3 hours. Thanks to the automatic feed, the feed is dosed, and this is already a good savings.

Factory made feeders

Factory feeders for chickens are presented in a variety of modifications. Cheap options are offered to poultry farmers in the form of feed containers with trays or without a hopper. Expensive models already come with a timer, and a special mechanism is installed to scatter the feed. The cost of such automatic feeders starts from 6 thousand rubles. The set timer automates the feeding process. The owner only needs to set the right time and fill the hopper with feed in time, and the automatic feeder will do the rest. Feeders are usually made of plastic or powder-coated sheet metal.

Cheap models with a tray and a hopper are a ready-to-use design. The poultry farmer only needs to fill the container with feed and make sure that it does not end.

A very cheap automatic feeder is sold in only one tray. The poultry farmer himself needs to look for what to make a bunker from. Typically, these trays have a special mount, designed for a glass jar or plastic bottle.

For expensive automatic feeders, an additional installation of a drum with a volume of at least 20 liters is required. The photo shows how such a structure is mounted on steel pipe racks. The mechanism itself is installed from the bottom of the barrel. It works from ordinary batteries or a rechargeable battery. The timer sets the response time of the mechanism for scattering grain. In the automation settings, even the amount of feed poured out is regulated.

The use of expensive automatic feeders is beneficial when keeping a large number of chickens. For a small number of birds, small cheap products are suitable.

Primitive bucket feeder

Now we will look at how a primitive do-it-yourself chicken feeder with automatic feed is made. For its manufacture, you need any plastic container for the hopper and tray. For example, let’s take a bucket with a capacity of 5-10 liters from water-based paint or putty. This will be the bunker. For the tray, you need to find a bowl of a larger diameter than a bucket with a side height of about 15 cm.

An automatic feeder is made using the following technology:

- Small windows are cut out at the bottom of the bucket with a sharp knife. They need to be done in a circle with a step of about 15 cm.

- The bucket is placed in a bowl, and the two bottoms are pulled together with a self-tapping screw or bolt. With good glue, the bunker can be simply glued to the tray.

That’s the whole technology of manufacturing auto feeders. The bucket is filled to the top with dry food, covered with a lid and placed in a chicken coop. If desired, such a feeder can be hung at a small height from the floor. To do this, the rope is tied at one end to the handle of the bucket, and the other end is fixed with a bracket on the ceiling of the house.

Bunker automatic feeders made of wood

Automatic feeders made of plastic buckets, bottles and other containers are only good for the first time. In the sun, plastic dries up, cracks, or simply such structures deteriorate from accidental mechanical influences. It is best to make a reliable hopper-type automatic feeder out of wood. Any sheet material such as chipboard or plywood is suitable for work.

Bunker automatic feeder without pedals

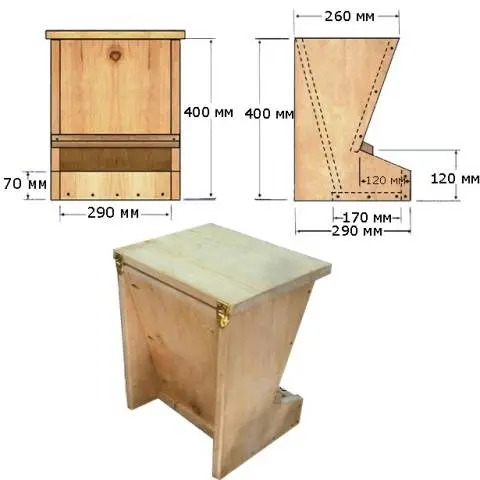

The simplest version of a wooden automatic feeder is a hopper with a lid, at the bottom of which there is a grain tray. The photo shows a drawing of such a design. On it, you can carve out fragments of an auto-feeder from sheet material.

The procedure for making a feeder is as follows:

- The presented scheme already contains the sizes of all fragments. In this example, the length of the automatic feeder is 29 cm. Since one adult chicken should have 10–15 cm of a food tray, this design is designed for 2–3 individuals. For more chickens, you can make several automatic feeders or calculate your own sizes.

- So, all the details from the scheme are transferred to the sheet material. You should get two side shelves, a bottom, a lid, a side of the tray, a front and a back wall. The fragments are cut out with a jigsaw, after which all the ends are cleaned with sandpaper from burrs.

- Along the edges of the parts where they will be connected, holes for hardware are made with a drill. Further, according to the drawing, all the parts are connected into a single whole. When assembling the feeder hopper, make sure that the front and rear walls are at an angle of 15о inside the structure.

- The top cover is made opening on hinges.

The finished feeder is impregnated with an antiseptic. After the impregnation dries, grain is poured into the bunker, and the product is placed in the chicken coop.

Bunker automatic feeder with pedal

The next type of wooden automatic feeder consists of the same hopper with a tray, only we will automate this design with a pedal. The principle of operation of the mechanism is that the pedal will be pressed by chickens. At this time, the lid of the tray is lifted through the rods. When the chicken is full, she moves away from the feeder. The pedal rises, and with it the lid closes the feed tray.

For the manufacture of an auto-feeder with a pedal, the previous scheme is suitable. But the size should not be increased. For the mechanism to work, the chicken on the pedal must be heavier than the lid of the tray.

First you need to make a bunker feeder. We have already considered it. But when drawing up the drawing, you need to add two rectangles for the tray cover and the pedal. Rods are made of six bars. Take the two longest blanks. They will hold the pedal. Two bars of medium length are prepared to fix the tray lid. And the last two shortest bars will go to the connection of long and medium blanks that form the lifting mechanism. The dimensions of all elements of the pedal mechanism are calculated individually according to the dimensions of the feeder.

When the automatic feeder is ready, proceed to install the pedal mechanism:

- Two bars of medium length are fixed with screws to the tray cover. At the other end of the bars, 2 holes are drilled. The fixation of the mechanism will occur with the help of bolts. To do this, the extreme holes located closer to the end of the bars are drilled with a larger diameter than the bolt itself. The same holes are also drilled in the side shelves of the feeder hopper. Next, a bolted connection is made so that the bars move freely along the axis of the bolts, and lift the cover.

- By a similar method, the pedal with the longest bars is fixed. The same holes are drilled, only those into which the bolts for connecting to the hopper will be inserted are located at 1/5 of the length of the bar.

- Two short bars connect the entire mechanism. On these blanks, holes are drilled along the edges. At the ends of long and medium bars, they are already there. Now it remains to connect them with bolts only rigidly, otherwise the cover will not rise when the pedal is pressed.

The operation of the mechanism is checked by pressing the pedal. If the cover does not lift, the rigid connection bolts must be tightened further.

On the video automatic feeder:

Conclusion

As you can see, if you wish, you can make an auto-feeder yourself. This will save your home budget, and equip the chicken coop at your discretion.