Contents

Alcoholic fermentation underlies the preparation of any alcoholic beverage. This is the easiest and most affordable way to get ethyl alcohol. The second method – ethylene hydration, is synthetic, rarely used and only in the production of vodka. We will look at the features and conditions of fermentation to better understand how sugar is converted to alcohol. From a practical point of view, this knowledge will help to create the optimal environment for yeast – to put mash, wine or beer correctly.

Alcoholic fermentation Yeast converts glucose into ethyl alcohol and carbon dioxide in an anaerobic (oxygen-free) environment. The equation is the following:

C6H12O6 → 2C2H5OH + 2CO2.

As a result, one molecule of glucose is converted into 2 molecules of ethyl alcohol and 2 molecules of carbon dioxide. In this case, energy is released, which leads to a slight increase in the temperature of the medium. Fusel oils are also formed during the fermentation process: butyl, amyl, isoamyl, isobutyl and other alcohols, which are by-products of amino acid metabolism. In many ways, fusel oils form the aroma and taste of the drink, but most of them are harmful to the human body, so manufacturers try to purify alcohol from harmful fusel oils, but leave useful ones.

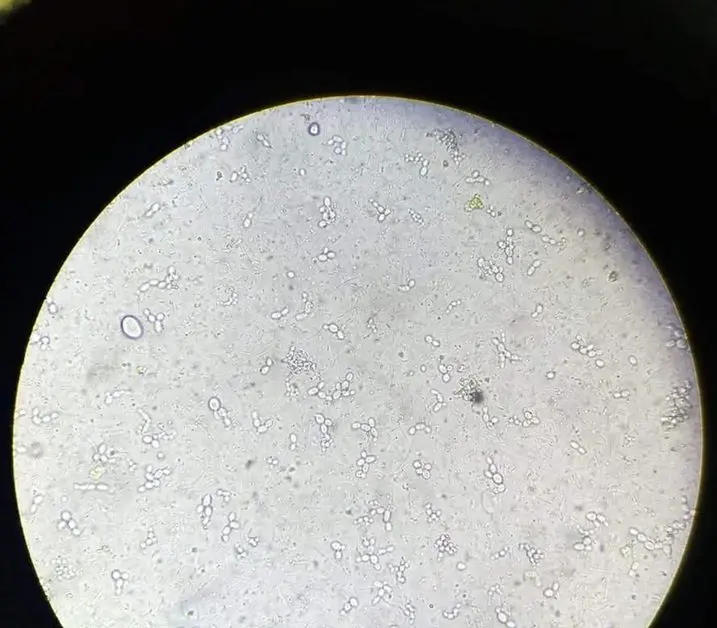

Yeast – These are unicellular spherical fungi (about 1500 species), actively developing in a liquid or semi-liquid medium rich in sugars: on the surface of fruits and leaves, in the nectar of flowers, dead phytomass and even soil.

This is one of the very first organisms “tamed” by man, mainly yeast is used for baking bread and making alcoholic beverages. Archaeologists have found that the ancient Egyptians for 6000 years BC. e. learned how to make beer, and by 1200 BC. e. mastered the baking of yeast bread.

The scientific study of the nature of fermentation began in the XNUMXth century, the first chemical formula was proposed by J. Gay-Lussac and A. Lavoisier, but the essence of the process remained unclear, two theories arose. The German scientist Justus von Liebig suggested that fermentation is mechanical in nature – the vibrations of the molecules of living organisms are transmitted to sugar, which is split into alcohol and carbon dioxide. In turn, Louis Pasteur believed that the basis of the fermentation process is biological in nature – when certain conditions are reached, the yeast begins to process sugar into alcohol. Pasteur managed to prove his hypothesis empirically, later the biological nature of fermentation was confirmed by other scientists.

The Russian word “yeast” comes from the Old Slavonic verb “drozgati”, which means “to crush” or “knead”, there is a clear connection with baking bread. In turn, the English name for yeast “yeast” comes from the Old English words “gist” and “gyst”, which mean “foam”, “to give off gas” and “boil”, which is closer to distillation.

As a raw material for alcohol, sugar, sugar-containing products (mainly fruits and berries), as well as starch-containing raw materials: grain and potatoes are used. The problem is that yeast cannot ferment starch, so you first need to break it down to simple sugars, this is done by an enzyme called amylase. Amylase is found in malt, a germinated grain, and is activated at high temperature (usually 60-72 ° C), and the process of converting starch to simple sugars is called “saccharification”. Saccharification with malt (“hot”) can be replaced by the introduction of synthetic enzymes, in which the wort does not need to be heated, therefore the method is called “cold” saccharification.

Fermentation conditions

The following factors influence the development of yeast and the course of fermentation: sugar concentration, temperature and light, acidity of the environment and the presence of trace elements, alcohol content, oxygen access.

1. Sugar concentration

For most yeast races, the optimal sugar content of the wort is 10-15%. At concentrations above 20%, fermentation weakens, and at 30-35% it is almost guaranteed to stop, since sugar becomes a preservative that prevents yeast from working.

Interestingly, when the sugar content of the medium is below 10%, fermentation also proceeds poorly, but before sweetening the wort, you need to remember the maximum concentration of alcohol (4th point) obtained during fermentation.

2. Temperature and light

For most yeast strains, the optimum fermentation temperature is 20-26°C (bottom-fermenting brewer’s yeast requires 5-10°C). The allowable range is 18-30 °C. At lower temperatures, fermentation slows down significantly, and at values below zero, the process stops and the yeast “falls asleep” – falls into suspended animation. To resume fermentation, it is enough to raise the temperature.

Too high a temperature will kill the yeast. The threshold of endurance depends on the strain. In general, values above 30-32 °C are considered dangerous (especially for wine and beer), however, there are separate races of alcohol yeast that can withstand wort temperatures up to 60 °C. If the yeast is “cooked”, you will have to add a new batch to the wort to resume fermentation.

The fermentation process itself causes a temperature increase of several degrees – the larger the volume of the wort and the more active the yeast, the stronger the heating. In practice, temperature correction is done if the volume is more than 20 liters – it is enough to keep the temperature below 3-4 degrees from the upper limit.

The container is left in a dark place or covered with a thick cloth. The absence of direct sunlight avoids overheating and has a positive effect on the work of yeast – fungi do not like sunlight.

3. Acidity of the environment and the presence of trace elements

Medium acidity 4.0-4.5 pH promotes alcoholic fermentation and inhibits the development of third-party microorganisms. In an alkaline environment, glycerol and acetic acid are released. In neutral wort, fermentation proceeds normally, but pathogenic bacteria actively develop. The acidity of the wort is corrected before adding the yeast. Often, amateur distillers increase the acidity with citric acid or any acidic juice, and to reduce the must, they quench the must with chalk or dilute it with water.

In addition to sugar and water, yeast requires other substances – primarily nitrogen, phosphorus and vitamins. These trace elements are used by yeast for the synthesis of amino acids that make up their protein, as well as for reproduction at the initial stage of fermentation. The problem is that at home it will not be possible to accurately determine the concentration of substances, and exceeding the permissible values uXNUMXbuXNUMXbcan negatively affect the taste of the drink (especially for wine). Therefore, it is assumed that starch-containing and fruit raw materials initially contain the required amount of vitamins, nitrogen and phosphorus. Usually only pure sugar mash is fed.

4. Alcohol content

On the one hand, ethyl alcohol is a waste product of yeast, on the other hand, it is a strong toxin for yeast fungi. At an alcohol concentration in the wort of 3-4%, fermentation slows down, ethanol begins to inhibit the development of yeast, at 7-8% the yeast no longer reproduces, and at 10-14% they stop processing sugar – fermentation stops. Only individual strains of cultured yeast, bred in the laboratory, are tolerant of alcohol concentrations above 14% (some continue to ferment even at 18% and above). About 1% alcohol is obtained from 0.6% sugar in the wort. This means that to obtain 12% alcohol, a solution with a sugar content of 20% (20 × 0.6 = 12) is required.

5. Oxygen access

In an anaerobic environment (without access to oxygen), yeast is aimed at survival, not reproduction. It is in this state that the maximum alcohol is released, so in most cases it is necessary to protect the wort from air access and at the same time organize the removal of carbon dioxide from the tank in order to avoid increased pressure. This problem is solved by installing a water seal.

With constant contact of the wort with air, there is a danger of souring. At the very beginning, when fermentation is active, the released carbon dioxide pushes air away from the surface of the wort. But at the end, when fermentation weakens and less and less carbon dioxide appears, air enters the uncovered container with the wort. Under the influence of oxygen, acetic acid bacteria are activated, which begin to process ethyl alcohol into acetic acid and water, which leads to spoilage of wine, a decrease in the yield of moonshine and the appearance of a sour taste in drinks. Therefore, it is so important to close the container with a water seal.

However, yeast requires oxygen to multiply (to reach its optimal amount). Usually, the concentration that is in the water is enough, but for accelerated reproduction of the mash, after adding the yeast, it is left open for several hours (with air access) and mixed several times.

Molto completo