Contents

A do-it-yourself drawing of a sow farrowing machine can be developed if you know exactly the dimensions and design of the structure. If there is little experience, the scheme can be found in the subject literature or on the Internet. The farrowing cage has a simple device. To make it, you need to have the skills of a welder.

Benefits of using the machine

Many rural pig breeders save on the purchase or manufacture of a machine. For farrowing, sows simply equip a warm barn. The decision is wrong, since the presence of the machine allows you to get more profit in the future.

During farrowing, a sow usually brings up to 18 piglets. In good conditions, young growth grows rapidly, gaining weight. If all the livestock survive and grow, then the owner will receive a good profit. However, at lactation age there is a risk of death of piglets. The reason may be a lack of milk, the refusal of the sow to feed, the poor condition of the babies. In most cases, the pig breeder cannot influence these processes. However, there is another problem. Up to 14% of the case is due to mechanical damage. After farrowing, the sow lies on her side most of the time. During the day, she gets up about 15 times, lies down, turns over to the other side for the convenience of feeding. During such movements, suckers fall under the heavy side of the pig, maimed or simply strangled. The assembled cage for the sow at home minimizes the risk of mechanical damage to the offspring.

Inexperienced owners may confuse a farrowing crate with a crate used for insemination. In fact, the designs are different in purpose. The insemination machine allows you to firmly fix the pig during fertilization. It is not suitable for farrowing. Similarly, pens designed for other animals will not work.

Having a farrowing pen in stock, the owner receives many advantages:

- The ideal conditions for a safe farrowing are created for the pig.

- Decreases the number of death of the offspring.

- Improved feeding comfort for sucklings. Piglets get stronger faster, gain weight.

- Simplified care of the sow. It is easier for the owner to clean up waste, since they are not scattered throughout the pigsty. In addition, less bedding material is required to cover a small area.

- The inseminating pen cannot be used for farrowing, but in reverse it is possible. If necessary, a pig is clamped in the farrowing structure during artificial insemination.

After weighing all the advantages and future profits, it is more profitable for the pig breeder to bear the initial costs of manufacturing the machine.

Requirements for pens for pregnant sows

On pig farms, pregnant sows are kept in group pens for about 6-10 heads. Structures are made of stainless steel or black metal with a galvanized coating. Sometimes they are just painted. There are machines made of durable plastic for group keeping of sows. However, their frame itself is made of metal. Plastic only gates and partitions.

Group structures are equipped with feeders, nipple-type drinkers. For pregnant sows, they provide free and individual maintenance in a group pen. Separate compartments are used to fix the pig during the examination by the veterinarian.

Regardless of whether the machine is group or single, home-made or factory-made, a number of requirements are imposed on the design. If the cage meets the standards, the work of the pig breeder will be greatly facilitated, since he will have to clean, control the offspring and the sow, and feed. The machine will be examined by a veterinarian, if necessary, treatment and other actions will be carried out.

In order for a do-it-yourself machine for a sow to become a real helper on the farm, it must meet the following requirements:

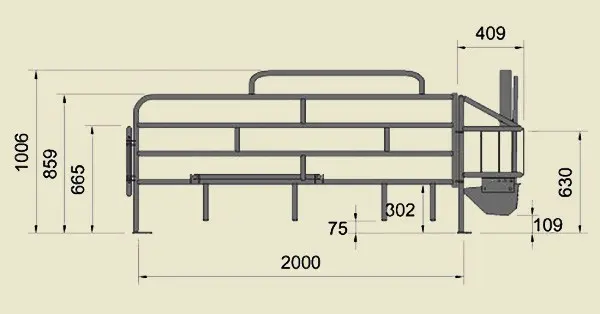

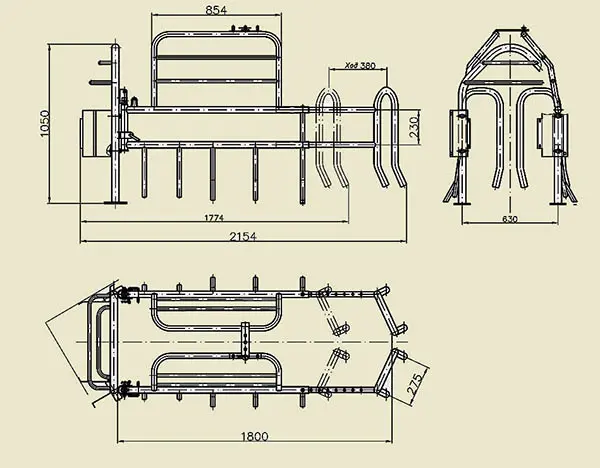

- Dimensions. On sale you can see machines for farrowing of different sizes. This is not a marriage. Models are designed for different breeds. The weight of a sow can vary from 100 to 300 kg. When self-manufactured, the dimensions are calculated taking into account the contained rock. Usually, the width of the machines is made from 50 to 70 cm. The minimum length is 140 cm, but the indicator is similarly increased taking into account the length of the sow. The height of the structure is limited to 110 cm. A gap of 30 cm is maintained between the floor and the lower pipe of the machine.

- Материал. The strength of a home-made design for farrowing is provided only by metal. There are several options here. It is cheaper to weld a cage from an ordinary pipe, but it will have to be cleaned and painted every year. Black metal rusts quickly. Galvanized pipes are considered the best choice in terms of price and quality. Stainless steel is the ideal material. The disadvantage of such pipes is the high cost.

- Practicality. Breeds of farmed pigs can change over the years. It is not profitable to make a new farrowing cage every time. It is optimal to immediately make a sliding structure with the ability to adjust the size to fit the sow’s physique.

- Location type. Machines are installed diagonally or straight. Owner’s choice. However, diagonal models are more difficult to clear manure. In addition, sow teats are more likely to be injured in such cages.

- Floor. So that the machine is not cleaned of manure several times a day, the flooring is made with slots. The size of the gaps cannot be overestimated. In large gaps on the floor, the hooves of a standing pig will get stuck, the sow’s nipples during feeding, when the female lies on her side.

A machine purchased or made independently is placed in a farrowing box. The compartment must be spacious. In addition to the site for the cage, the box provides a space where the kids will run. Optimally prepare a box with an area of 4,5 m for the machine2.

How to make a farrowing cage for pigs

To make a cage, you will need a drawing, metal and welding skills. The process will go faster if it is possible to see the device of the finished machine in reality.

Tools and materials

When assembling a sow farrowing machine with your own hands, you will need to stock up on materials:

- pipe with a diameter of 25-40 mm;

- knees of a similar section;

- loops for the gate;

- welding electrodes;

- cutting wheels on the grinder.

From the tool you can not do without a welding machine and a grinder. Additionally, you need a hammer, pliers.

Drawings, dimensions

It is easier to assemble a cage according to ready-made drawings. The dimensions can be saved if they are suitable for the body type of the sow. Otherwise, the animal is subjected to measurement. Be sure to make a small margin, because over time the sow is able to recover.

Assembly process

When all the tools and materials are prepared, the dimensions are determined, there is a drawing at hand, they begin to assemble the farrowing cage:

- Adhering to the dimensions of the drawing, blanks are cut from pipes with a grinder. Each element is numbered so as not to be confused.

- Prepared blanks are welded into a single structure. Where turns are required, elbows are welded to the pipes.

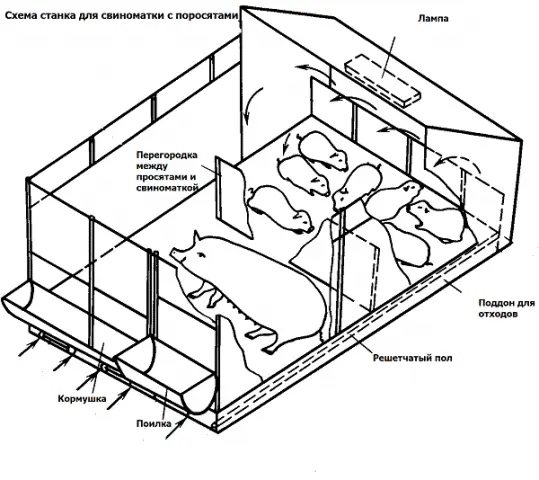

- A feeder is attached to the front of the cage at a height of 50 cm from the floor.

- In the fenced structure, an opening for the gate is left. The door is hinged so that it opens outward and inward. Be sure to provide a heck.

- The design of the cell consists of arcs and gratings. Additionally, shutters are made. The elements allow you to fix the sow in a lying position or standing, which reduces the risk of crushing suckers.

All structural elements must be securely fastened. The requirement also applies to feeders and drinkers.

The video shows a sample of the machine:

Design installation

At the time of manufacture of the cage, a box should be prepared where it will be located. The room is insulated, exclude the possibility of drafts, equip natural ventilation. Air ducts are equipped with adjustable dampers.

The cell can be made mobile or stationary. If the second option is chosen, the structure is immediately welded to concreted posts. Fixation is carried out with corners. A gap is left under the floor to allow the drawer to be inserted.

Indoors, the machine is positioned so that there is a free approach for suckers on both sides. Drinking bowls with a feeder are attached to one side of the cage, and a red lamp is securely fixed in a protective net on the opposite wall. It will serve as a source of light and heating.

Terms of Use

To make the sow and sucklings comfortable, they maintain a temperature regime in the range of 32-37 оC. If the box is well insulated, a 150 W lamp will provide the required temperature in the area of uXNUMXbuXNUMXbthe cage. The control is carried out with a conventional thermometer.

The floor of the sow is laid soft. Make sure you have food and water available. If during farrowing the drinker is empty, the pig is able to eat the offspring. Ventilation is regulated by dampers to obtain high-quality air exchange.

Conclusion

It is more convenient to develop a drawing of a machine for farrowing a sow with your own hands because of taking into account all the nuances. The owner customizes the design to suit his needs, taking into account the peculiarities of the location in the box.