Contents

How does 3D food printing work, what exactly are its benefits, and what are the best options? It is what we learn today.

La 3d food printing offers a variety of potential benefits in the restaurant industry.

Some of these benefits are for health, but we also find positive contributions for the environment and, above all, for customers, who find an attractive door open towards personalizing food according to individual needs and preferences.

3D food printing

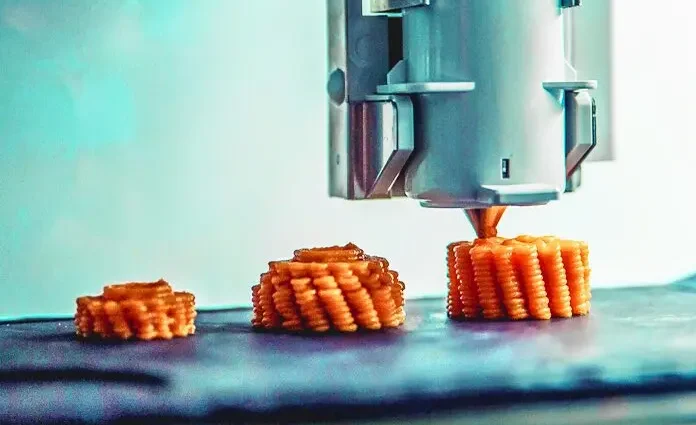

3D printing is here to stay. This is known by manufacturers and companies in a wide spectrum of industries, such as automotive, aerospace and, now, food. Yes. As you are reading it: 3D food printing is now literally on the table of restaurants as one of the most interesting technological innovations that this 2021 raises.

3D food printing is not an idea today, nor is it a project. It is a reality that will revolutionize food production, creative possibilities, personalization and sustainability. But by now, you probably want to know right away how 3D food printing works. Let’s see:

3D Food Printing – How does it work?

3D printing, or additive manufacturing, works with machines that “extrude” filaments of various materials, plastic or metallic, in layers, according to a program entered from a CAD or STL data file.

The machine has the ability to interpret the instructions, and deposit the building material one layer at a time. 3D food printing posed an initial challenge related to the consistency and viscosity required by the process for the material to emerge smoothly from the nozzle and maintain its shape as it deposited.

At first, the idea of sitting down to eat a plate that is the result of an extruded mixture will not be very attractive to your customers. But when they notice that the food is tasty, and that, on the fly, they have the possibility to influence the preparation of pasta, sausage, breadsticks and many breakfast cereals, the “impression” is sure to change.

What foods can be produced with 3-D printing?

Chocolate is one of the easiest ingredients to extrude through a 3D printing nozzle. Chocolate allows you to create complex and creative designs directly, adding customization possibilities that are unprecedented in the food industry.

Smooth, flowable products like cream cheese and mashed potatoes are also easy to work with. But the extrusion systems with multiple nozzles will allow you to add much more complex entrances, such as pizzas, cake dough, different baked goods and, above all, sweets in all their representations.

In Los Angeles, Starbucks produces a vegan, milk-free, plant-based ice cream using 3D printing. The flavors available are Berry, Mango, Coconut, Vanilla and, of course, Chocolate.

At the moment there are still some limitations. The preparation of gelatin is one of them. But, 3D printer manufacturers are working to offer machines that can offer personalized food options in all food groups, in a term no longer than three years.

Why implement 3D food printing?

By now, you’re probably thinking that adopting 3D food printing will barely win you over a few customers who want to get a chocolate cake with their name written on it.

Well the news is that this is not the case. In addition to boosting culinary creativity and allowing nutritional customization of ingredients, 3D food printers offer many more benefits. These are some of the most relevant:

- Save time, money and work– 3D food printing saves time and labor, when it comes to experimenting with toppings for new preparations or for cake decorations. An experienced and highly skilled pastry chef will never be able to obtain the results that 3D printing offers, in a short time and with very little effort.

- Introduction of healthy ingredients: In the Netherlands, a food designer creates cookie-like yeast structures that include spores and seeds that sprout over time. This type of food, natural and transportable, will undoubtedly transform the food industry in a short time.

- Impact on the environment– 3D printing eliminates ingredient waste, using only the exact amount required to make a food. The impact is even greater in the case of 3D-printed meat, which, according to Maastricht University reports, would reduce greenhouse gas emissions by 96%. Finally, to conclude this item, it will no longer be necessary to incur transportation costs for prepared foods. It will hardly be necessary to send a file, so that the same food, with the same properties and characteristics, can be produced anywhere on the planet.

3D Food Printing – The Best Choices

In practice, all manufacturers could supply equipment to implement 3D food printing. However, some of them have advanced in the production of machines specially designed to reach the kitchen of your restaurant, without you having to make adaptations or experiment until you find the ideal configuration. These are the best options:

Dovetailed

Dovetailed is a Microsoft development for 3D food printing based on fruits and vegetables. This 3D printer uses a revolutionary molecular technique, called “spherification”, which makes it possible to obtain special fruit flavors from the juice of the same in combination with powdered socio alginate. The end result is a completely organic product.

ByFlow

The ByFlow company is of Dutch origin and has developed its “Focus” model exclusively for use in the food industry. This machine allows to use prepared foods, to create new complete products. Such is the functionality of “Focus” that this year the first 100% restaurant with food printed in “Focus” will open.

CocoJet

This is the exclusive chocolate printer. It is a product of the manufacturer 3D Systems, in collaboration with the giant of the chocolate industry Hershey’s Company. This machine offers functionalities that make it perfect for lovers of this food, and for the most demanding pastry chefs.

Foodini

Natural Machines, a Catalan company based in Barcelona, has developed Foodini, a 3D printer equipped with various types of nozzles, which allows printing of almost all possible materials. Its manufacturer promotes it as the “Printer of health food.” It is undoubtedly the local option to start in 3D food printing.